The market’s requirements for product precision are getting higher and higher. In the pursuit of ultimate precision, How Five-Axis CNC Machining Surpasses Traditional Machining?

one. Limitations of traditional processing methods

Traditional processing methods,Such as three-axis CNC machine tools,Although it meets the needs of industrial production to a certain extent,But when faced with complex curved surfaces and high-precision requirements,But it seems powerless。Toolpath restricted,Difficult to reach every corner of the workpiece,Lead to low processing efficiency,And it is difficult to ensure processing accuracy。These limitations limit the development of manufacturing,making high precision、Processing of complex curved surfaces becomes a problem。

two. The rise of five-axis CNC machining technology

1.Multi-axis linkage,Broaden processing scope

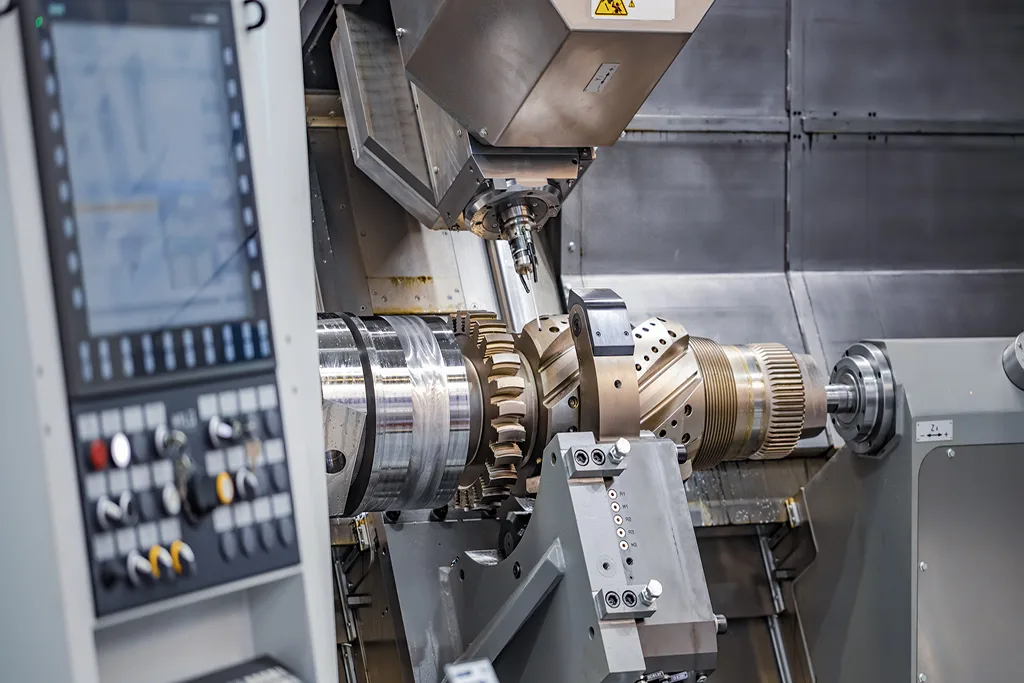

The biggest feature of five-axis CNC machining technology is its multi-axis linkage function。In the original X、Y、Z is based on three linear motion axes,Two axes of rotation are added (usually A、B or C axis),Allows the tool to move freely in three-dimensional space,Achieve precise machining of complex curved surfaces。This multi-axis linkage method,Greatly expands processing scope,Improved processing efficiency。

2.Efficient processing,Improve production efficiency

Five-axis CNC machining technology optimizes tool paths and cutting parameters,Efficient processing achieved。Multi-faceted processing can be completed in one clamping,Reduces the number of repeated clampings,Significantly improved production efficiency。at the same time,High-speed cutting capabilities of five-axis machine tools,Further shortening the processing cycle,Reduced production costs。

3.Extreme precision,Meet high demands

Five-axis CNC machining technology with its high-precision control capabilities,Meets market demand for high-precision products。The five-axis linkage function can control the processing angle with extremely high precision.,Ensure the accuracy of processed parts。also,Advanced control systems and programming software,Make the processing process more stable、reliable,Further improved processing accuracy。

three、Application of five-axis CNC machining in various fields

Five-axis CNC machining technology in aerospace、automobile manufacturing、Mold manufacturing and other fields have been widely used。These fields require extremely high precision and complexity of products,Five-axis CNC machining technology with its excellent performance,successfully solved these problems,Promoted the development of manufacturing industry。

After reading this article, you have learned How Five-Axis CNC Machining Surpasses Traditional Machining. In the pursuit of ultimate precision, Rapid Efficient’s efficient, accurate and reliable processing capabilities have become the first choice for many companies. Rapid Efficient not only has powerful processing capabilities and flexibility, but is also equipped with advanced control systems and programming software to make operations easier and more efficient. Whether it is processing complex surfaces or achieving high-precision requirements, Rapid Efficient can easily cope with it and create greater value for the company.