Introduction

In today’s highly industrialized world, precision CNC and lathe machining services play a crucial role in various industries. These advanced manufacturing techniques offer a level of accuracy and efficiency that is essential for producing high-quality components and products.

Precision CNC machining services utilize computer numerical control (CNC) technology to automate the machining process. This allows for the production of complex parts with extremely tight tolerances. CNC machines can perform a wide range of operations, including milling, turning, drilling, and grinding. They are capable of working with a variety of materials, such as metals, plastics, and composites.

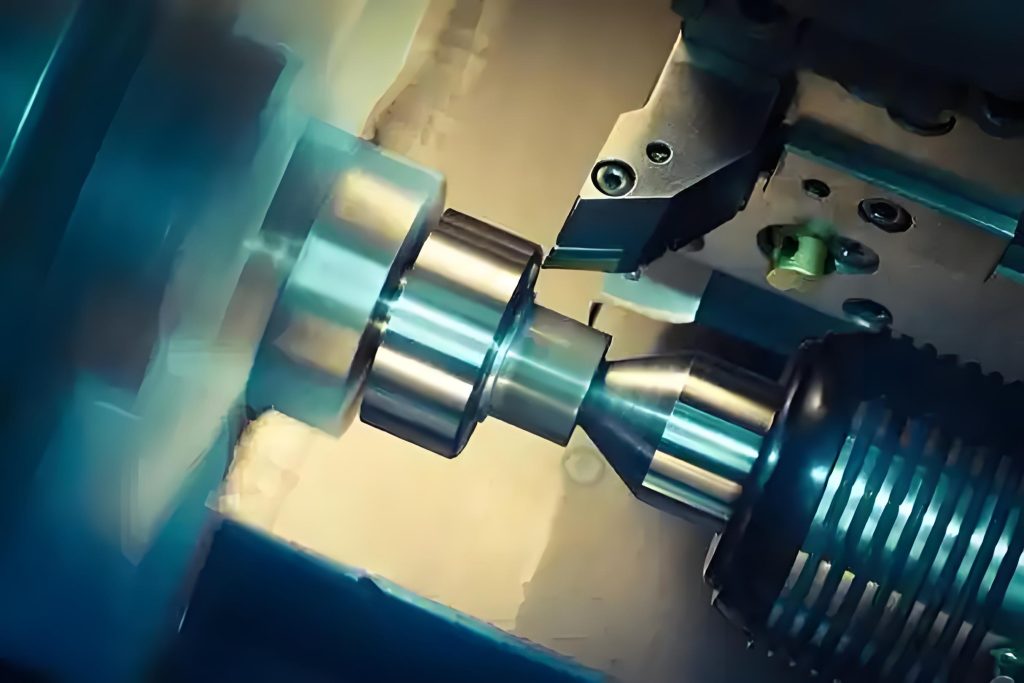

Lathe machining, on the other hand, is a traditional machining process that involves rotating a workpiece on a spindle while a cutting tool is applied to shape the material. Lathes are particularly useful for producing cylindrical parts and can achieve high levels of precision and surface finish.

The importance of these machining services cannot be overstated. In the automotive industry, for example, precision CNC and lathe machining are used to produce engine components, transmission parts, and suspension systems. These parts must meet strict quality standards to ensure the safety and performance of the vehicle.

In the aerospace industry, precision machining is essential for manufacturing components such as turbine blades, landing gear parts, and structural components. The high demands for strength, light weight, and reliability in aerospace applications require the use of advanced machining techniques.

The medical industry also relies on precision machining services to produce surgical instruments, implants, and other medical devices. These products must be manufactured with the highest level of precision to ensure patient safety and effectiveness.

In addition to their importance in specific industries, precision CNC and lathe machining services offer several benefits to manufacturers. One of the main advantages is the ability to produce complex parts with high accuracy and repeatability. This reduces the need for manual labor and increases production efficiency.

Another benefit is the flexibility offered by these machining services. Manufacturers can quickly and easily change the design of a part by modifying the CNC program, allowing for rapid prototyping and product development.

Furthermore, precision machining services can help reduce waste and material costs. By using advanced cutting tools and optimized machining processes, manufacturers can minimize material removal and maximize the utilization of raw materials.

In conclusion, precision CNC and lathe machining services are essential for modern manufacturing. Their advanced technologies and capabilities enable the production of high-quality components and products across a wide range of industries. Whether it’s the automotive, aerospace, medical, or any other industry, these machining services play a crucial role in ensuring the success of manufacturing operations.

What are CNC and Lathe Machining Services?

CNC (Computer Numerical Control) machining and lathe machining are essential processes in modern manufacturing. These services involve the use of computer-controlled machines to shape and cut materials with high precision.

CNC machining services utilize advanced computer technology to automate the manufacturing process. It is a highly versatile method that can perform a wide variety of operations, including milling, turning, drilling, and grinding. With CNC machining, manufacturers can produce complex parts with extremely tight tolerances. The process starts with a digital design created using computer-aided design (CAD) software. This design is then translated into a set of instructions that the CNC machine follows to shape the material.

Lathe machining, on the other hand, is a traditional machining process that has been refined over the years. It involves rotating a workpiece on a spindle while a cutting tool is applied to shape the material. Lathes are particularly useful for producing cylindrical parts and can achieve high levels of precision and surface finish. Lathe machining can be used to create parts for a wide range of applications, from automotive components to medical devices.

Both CNC machining and lathe machining services offer several advantages to manufacturers. One of the main benefits is the high level of precision they provide. These processes can produce parts with extremely tight tolerances, ensuring that they fit together perfectly and function as intended. This is crucial in industries such as aerospace and medical device manufacturing, where even the slightest deviation can have serious consequences.

Another advantage is the efficiency of these services. Computer-controlled machines can operate continuously, reducing production time and increasing output. Additionally, the ability to program the machines to perform specific tasks means that manufacturers can quickly change production runs to meet changing customer demands.

Service, as defined in English, can mean “a service, an act of serving; military service; a ceremony.” As a verb, it can mean “to repair, maintain; provide service.” In the context of CNC and lathe machining services, service refers to the act of providing these precision manufacturing processes to customers. Manufacturers offer a range of services, including design and programming, machining, and quality control.

CNC machining services often involve working with a variety of materials, such as metals, plastics, and composites. The ability to work with different materials gives manufacturers the flexibility to create parts for different applications. For example, in the aerospace industry, lightweight composites are often used to reduce weight and increase fuel efficiency. In the medical industry, biocompatible materials are required to ensure patient safety.

Lathe machining services are also capable of working with different materials. Cylindrical parts made on a lathe can be used in a variety of applications, from engine components to furniture hardware. The precision and surface finish achieved by lathe machining make these parts not only functional but also aesthetically pleasing.

In conclusion, CNC and lathe machining services are integral to modern manufacturing. They offer high precision, efficiency, and flexibility, allowing manufacturers to produce complex parts for a wide range of industries. Whether it’s creating components for the aerospace industry or producing medical devices, these services play a crucial role in ensuring the quality and functionality of the final product.

Types of CNC and Lathe Machining Services

CNC Milling Service

CNC milling is a highly versatile and accurate machining process. It involves using a rotating cutting tool to remove material from a workpiece and create a specific shape. York Haven Fabricators, Inc., a state-of-the-art sheet metal fabrication and CNC machining company, offers precision CNC milling services. Their woman-owned family business under 2nd generation leadership has over one hundred precision CNC machining services customers in various markets, including military, medical, lighting, automotive, packaging, and energy industries.

CNC milling services utilize advanced computer technology to automate the manufacturing process. A digital design created using computer-aided design (CAD) software is translated into a set of instructions that the CNC machine follows to shape the material. This process can perform a wide variety of operations, including milling complex 3D shapes or applying machined surfaces or features to parts made of both plastics and metals.

DFM CNC SHOP provides a variety of precision CNC machining services, including milling. With precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and an experienced team, they can handle all types of CNC machining parts in both metal and plastic materials. Whether it’s for prototypes or production parts, their machining services are a great choice.

CNC Turning Service

CNC turning uses a lathe to rotate a workpiece while a cutting tool shapes it. This service is ideal for creating cylindrical parts and offers high precision and repeatability. Turning is a traditional machining process that has been refined over the years.

Component Supplies offers a complete CNC machining service, including CNC turning. They specialize in the precision manufacture of parts from all metals and sub-contract machining of customers’ own components. Working closely with clients, they offer quality, reliability, and commitment to ensure that the supply of machined components is within budget and time frame.

GrovTec Machining is known for its precision turned components and screw machine products. Their dedicated team of experienced machinists and cutting-edge equipment allow them to tackle projects of all sizes and complexities.

Swiss-type CNC Machining

Swiss-type CNC machining is specialized for small, complex parts. It offers high precision and is often used in industries such as medical and electronics.

Swiss type CNC machining by companies like AP MFG in Shenzhen, China, offers machining services for precision parts. Their facilities include 3 to 5 axis CNC milling machines, CNC lathe (turning) machines, and swiss type automatic lathe (swiss screw machines). Their plant passed ISO9001 certification, and the parts they machine are widely applied in industries like automation, electronics, automobile, and aviation.

SolidCAM’s Swiss-Type module for multi-axis machining centers and Swiss-Type machines can accelerate complex CNC operations and maximize productivity. It offers features like channel synchronization manager for optimizing machining operations, advanced 机床控制操作 (MCO) for Swiss-Type machines, full machine simulation for collision detection, and advanced post-processing using virtual machine ID (VMID).

Benefits of Precision CNC and Lathe Machining Services

High Precision

Precision CNC and lathe machining services are renowned for their ability to achieve micron-level precision. This high level of accuracy ensures that every component produced meets the most stringent quality standards and tight tolerances. Whether it’s for the aerospace industry where even the slightest deviation can have catastrophic consequences or the medical field where precision is crucial for patient safety, these services deliver consistent quality. For example, in the production of surgical instruments, the precision offered by these machining techniques allows for intricate designs and exact dimensions, ensuring the effectiveness and reliability of the devices.

Consistency

One of the significant advantages of CNC and lathe machining is the consistency it provides. Every part produced is identical, which is essential for mass production. This consistency is achieved through automated processes that follow a precise set of instructions. Unlike traditional machining methods that may be prone to human error and variation, CNC and lathe machining ensure that each part is exactly the same. This not only saves time and reduces waste but also guarantees that products will function as intended when assembled. In industries such as automotive and electronics, where large quantities of identical parts are required, this consistency is a major advantage.

Automation

Automated processes play a crucial role in precision CNC and lathe machining. By reducing human error, these processes increase production efficiency. Automated machines can operate continuously without the need for breaks, significantly increasing output. Moreover, the use of advanced computer technology allows for precise control over the machining process. This means that complex operations can be performed with ease and accuracy. For instance, the ability to program machines to perform specific tasks enables manufacturers to quickly adapt to changes in design or production requirements. This flexibility and efficiency make automated precision machining an essential part of modern manufacturing.

Flexibility

The flexibility offered by precision CNC and lathe machining is another significant benefit. Manufacturers can easily adapt to changes in design by simply modifying the computer program. This allows for rapid prototyping and product development. Whether it’s a small adjustment to an existing design or a completely new concept, these machining services can quickly produce samples for testing and evaluation. In addition, the ability to work with a variety of materials gives manufacturers the freedom to create parts for different applications. From metals and plastics to composites, precision machining can handle a wide range of materials, providing endless possibilities for product design and innovation.

Applications in Different Industries

Aerospace

In the aerospace industry, precision machining is used to create complex parts for engines and aircraft structures. The high demands for strength, light weight, and reliability in aerospace applications require the use of advanced machining techniques. CNC and lathe machining services play a crucial role in this industry. They can produce parts with extremely tight tolerances, ensuring the safety and performance of aircraft. For example, turbine blades, landing gear parts, and structural components are often made using these machining services. The precision offered by CNC and lathe machining is essential for meeting the strict quality standards of the aerospace industry.

Automotive Manufacturing

CNC and lathe machining are essential for producing engine components, body parts, and interior trim. In the automotive industry, large quantities of identical parts are required, and the consistency provided by these machining methods is a major advantage. Every part produced is identical, which saves time and reduces waste. Moreover, the efficiency of CNC and lathe machining allows for continuous production without the need for breaks, significantly increasing output. For example, engine components such as cylinders and pistons can be produced with high precision using these machining services. The ability to work with different materials also gives manufacturers the flexibility to create parts that meet the specific requirements of different automotive models.

Medical Equipment

The high precision required for medical devices makes these machining services ideal. Medical equipment such as surgical instruments, implants, and other medical devices must be manufactured with the highest level of precision to ensure patient safety and effectiveness. CNC and lathe machining can achieve micron-level precision, allowing for intricate designs and exact dimensions. The consistency and repeatability of these machining methods ensure that each device is identical and functions as intended. For example, implants for orthopedic surgeries need to fit perfectly to ensure proper healing and functionality. The flexibility offered by these machining services also allows for rapid prototyping and product development, enabling manufacturers to quickly adapt to changes in medical technology.

Mold Making

For mold making, precision machining ensures accurate and durable molds for various applications. Mold making is a complex process that requires high precision and accuracy. CNC and lathe machining services can produce molds with extremely tight tolerances, ensuring that the final products have the desired shape and quality. For example, in the production of plastic parts, molds made using these machining services can produce large quantities of identical parts with high quality. The ability to work with different materials gives manufacturers the freedom to create molds for different applications, from automotive parts to medical devices. The advanced computer technology used in CNC and lathe machining allows for precise control over the machining process, ensuring that the molds are made to the highest standards.

Leading Providers of CNC and Lathe Machining Services

In the realm of CNC and lathe machining services, several companies stand out for their exceptional expertise and capabilities.

One such company is York Haven Fabricators, Inc. As a state-of-the-art sheet metal fabrication and CNC machining company under 2nd generation leadership, it is a woman-owned family business that has over one hundred precision CNC machining services customers across various markets. These markets include military, medical, lighting, automotive, packaging, and energy industries. Their precision CNC milling services utilize advanced computer technology to automate the manufacturing process, enabling them to perform a wide variety of operations and create complex parts with high precision.

DFM CNC SHOP is another notable provider. With precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and an experienced team, they can handle all types of CNC machining parts in both metal and plastic materials. Whether it’s for prototypes or production parts, their machining services are highly regarded.

In addition to these companies, there are several leading CNC machining companies that offer a wide range of services. For example, GrovTec Machining is known for its precision turned components and screw machine products. Their dedicated team of experienced machinists and cutting-edge equipment allow them to tackle projects of all sizes and complexities.

Another company worth mentioning is Avanti Engineering, Inc. Since 1972, they have become a leader in the CNC machining industry. Their skilled engineers utilize cutting-edge technology to fabricate components with intricate designs and tight tolerances, offering fast turnaround times at competitive prices. They are ISO 9001:2015 certified, ensuring the highest quality standards.

These companies, along with many others in the industry, are constantly pushing the boundaries of what is possible with CNC and lathe machining services. Their commitment to quality, innovation, and customer satisfaction makes them leading providers in this important field.

Future Trends in Precision Machining

Integration of Artificial Intelligence

AI is set to revolutionize precision machining by playing a crucial role in optimizing machining processes and enhancing efficiency. In the realm of CNC and lathe machining services, artificial intelligence can be utilized to analyze vast amounts of data from previous machining operations. By learning from patterns and outcomes, AI algorithms can recommend the most optimal cutting parameters, tool paths, and machining strategies. This not only reduces trial and error but also significantly cuts down on production time and material waste.

For example, AI can monitor the condition of cutting tools in real-time. By detecting signs of wear and tear, it can prompt timely tool changes, ensuring consistent machining quality and avoiding costly damages to workpieces. Additionally, AI can predict potential machining errors and suggest preventive measures, further improving the overall reliability of the machining process.

In the context of precision machining for industries such as aerospace and medical device manufacturing, where even the slightest deviation can have serious consequences, AI-driven optimization is invaluable. It helps ensure that every component meets the most stringent quality standards and tight tolerances.

Internet of Things (IoT) Integration

The integration of the Internet of Things (IoT) is another significant trend in precision machining. IoT enables remote monitoring and management of machining equipment, bringing several benefits to manufacturers.

With IoT-enabled sensors installed on machining tools and equipment, manufacturers can gather real-time data on various parameters such as tool wear, spindle speed, cutting force, and temperature. This data can be transmitted to a central monitoring system, allowing operators to keep a close eye on the machining process from anywhere.

For instance, in the case of a large-scale manufacturing facility, managers can monitor multiple machining stations simultaneously and make informed decisions based on the data received. If a problem is detected, such as excessive tool wear or a sudden increase in temperature, alerts can be sent immediately, enabling prompt action to prevent equipment damage and production delays.

Moreover, IoT integration allows for predictive maintenance. By analyzing the data collected from sensors, manufacturers can predict when a tool or equipment is likely to fail and schedule maintenance in advance. This not only reduces downtime but also extends the lifespan of the machinery.

In conclusion, the integration of AI and IoT in precision machining holds great promise for the future. These technologies will continue to drive innovation and improve productivity, ensuring that CNC and lathe machining services remain at the forefront of modern manufacturing.

Conclusion

In conclusion, precision CNC and lathe machining services are truly essential for modern manufacturing. As technology continues to progress, these services will only become more advanced and indispensable.

The integration of artificial intelligence and the Internet of Things is set to transform the field even further. AI’s ability to optimize machining processes and enhance efficiency will lead to reduced trial and error, shorter production times, and less material waste. For example, in the aerospace industry, where precision is of utmost importance, AI can ensure that every component meets the strictest quality standards.

The IoT’s remote monitoring and management capabilities will also bring significant benefits. Manufacturers will be able to gather real-time data on machining equipment, enabling them to make informed decisions and prevent problems before they occur. Predictive maintenance will reduce downtime and extend the lifespan of machinery.

As we look to the future, it’s clear that precision CNC and lathe machining services will continue to play a crucial role in various industries. Whether it’s the aerospace, automotive, medical, or any other sector, these services will drive innovation and ensure the production of high-quality components and products.

Leading providers in the field will continue to push the boundaries of what’s possible, constantly improving their expertise and capabilities. They will adapt to new technologies and trends, ensuring that they can meet the evolving needs of their customers.

In conclusion, precision CNC and lathe machining services are not only important today but will remain at the forefront of modern manufacturing for years to come.