In the ever-evolving manufacturing industry, precision machining is a beacon of innovation, leading the industry towards intelligent manufacturing. This transformative technology not only increases productivity but also ensures unmatched quality and efficiency. Let’s take a closer look at Precision machining moves towards intelligent manufacturing.

Firstly, Precision Machining Enhances Product Accuracy

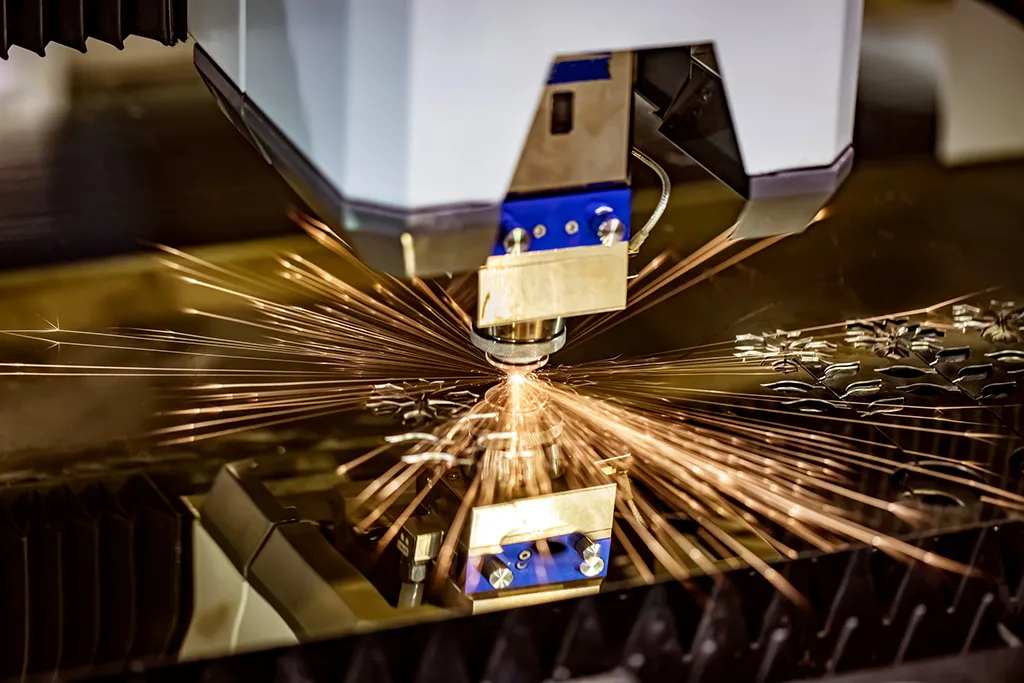

At the heart of smart manufacturing lies the pursuit of perfection in product accuracy. Precision machining employs advanced tools and techniques to achieve tolerances that were once unimaginable. This level of accuracy is crucial in industries such as aerospace, automotive, and medical devices, where even the slightest deviation can compromise performance and safety. By leveraging precision machining, manufacturers can produce components that meet the most stringent specifications, setting the foundation for smart manufacturing.

Moreover, Automation Integrates with Precision Machining

The integration of automation with precision machining marks a significant leap towards smart manufacturing. Automated systems can perform complex machining tasks with minimal human intervention, reducing errors and increasing throughput. This automation not only boosts productivity but also ensures consistency in quality across every batch. By automating precision machining processes, manufacturers can achieve a higher level of control and predictability, aligning with the principles of smart manufacturing.

Furthermore, Data Analytics Enhances Process Optimization

Smart manufacturing is not just about machines; it’s also about data. Precision machining generates vast amounts of data that can be analyzed to optimize processes and improve outcomes. By leveraging data analytics, manufacturers can identify bottlenecks, predict maintenance needs, and optimize machine settings for maximum efficiency. This data-driven approach to precision machining enables manufacturers to make informed decisions, continuously improving their processes and staying ahead of the competition.

Additionally, Precision Machining Supports Sustainable Manufacturing

In the age of sustainability, precision machining plays a vital role in reducing waste and promoting eco-friendly manufacturing practices. By accurately machining materials to the required specifications, manufacturers can minimize scrap and offcuts, reducing material waste. Furthermore, precision machining enables the use of lighter, stronger materials that contribute to more energy-efficient products. By supporting sustainable manufacturing, precision machining aligns with the growing consumer demand for environmentally responsible products.

In Conclusion, Precision Machining is the Future of Manufacturing

Through this article, we have learned about Precision machining moves towards intelligent manufacturing. As the manufacturing industry continues to develop, precision machining has become a key driver of intelligent manufacturing. By improving product accuracy, integrating automation, leveraging data analysis and supporting sustainable practices, precision machining lays the foundation for a brighter and more efficient manufacturing future. Manufacturers who adopt precision machining will be able to take full advantage of the opportunities brought by intelligent manufacturing and drive innovation and growth in the global economy.