Imagine a coin-sized piece of metal covered with a complex maze of microfluids, each channel with a width error of no more than 1/80th of a hair. This is not a sci-fi scene, but an everyday marvel created by modern precision metalworking technology. In core fields such as aerospace, high-end medical, precision instruments and electronic communications, the ultimate requirements for dimensional accuracy, geometric tolerance and surface quality of metal parts have pushed precision machining to the pinnacle of manufacturing.

Core Craftsmanship: “Dancing with the Tip of a Knife” in the Micron World

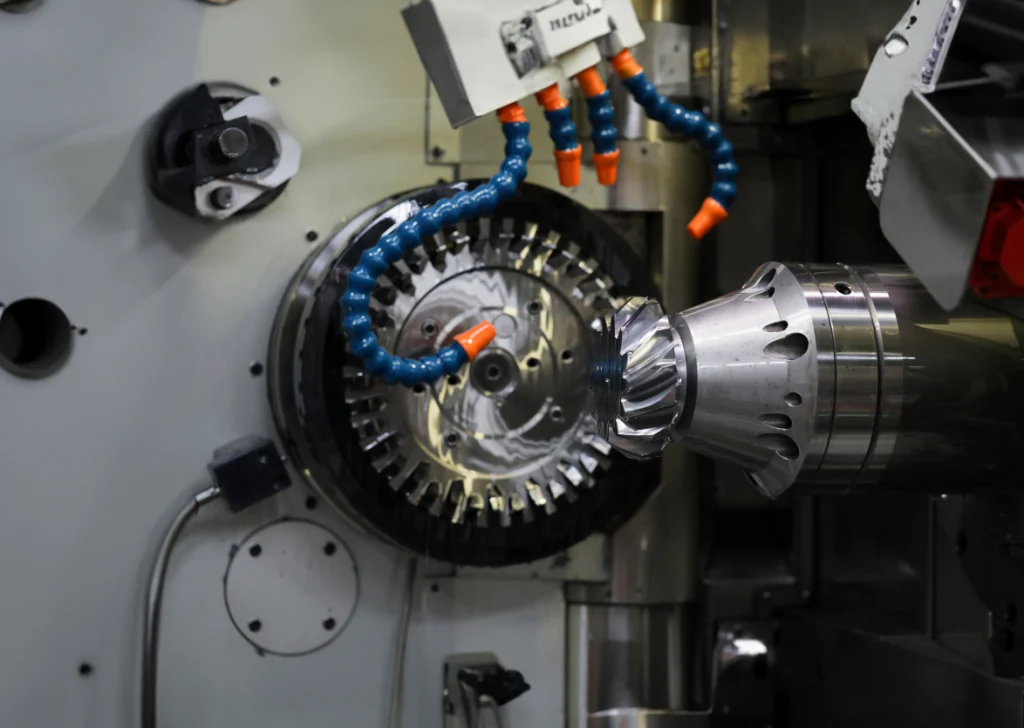

CNC Machining:The cornerstone of modern precision manufacturing. Multi-axis linkage machining centers (especially five-axis) are the core tools for machining complex curved surfaces and special-shaped structures. High-speed milling technology combines micro-diameter carbide or diamond tools to achieve micron-level accuracy and mirror effects on difficult-to-machine materials such as titanium alloys and superalloys. The turning center is good at the efficient forming of precision shaft and disc parts.

Ultra-precision turning/milling:In a constant temperature, ultra-clean, anti-vibration environment, natural single-crystal diamond tools are used to achieve sub-micron shape accuracy and nano-level surface roughness. It is used to process cutting-edge parts such as infrared optical components and laser gyroscope mirrors.

Slow Wire EDM (WEDM-LS):Utilizes extremely fine wire (typically 0.02-0.3mm) for discharge corrosion cutting. Its outstanding advantage is that it can process high-hardness materials (e.g. carbide, hardened steel), and can achieve extremely small internal corner radii (up to R0.015mm) and extremely high dimensional accuracy (±0.002mm is the norm for high-end equipment). It is indispensable in the processing of precision molds, medical bone nails, and micro gears.

Laser processing:The “cold processing” characteristics of ultrafast lasers (picosecond, femtosecond) make them significantly advantageous in precision micro-holes (aperture size can be as small as microns), cutting brittle materials (such as ceramics, sapphire), complex microstructure processing, and surface micro-texture treatment, with a very small heat-affected zone.

EDM Sinking and Micro EDM: Uses pulsed discharge between the electrode and the workpiece to erode the material. EDM is good at processing complex three-dimensional cavities, deep and narrow grooves and micro holes (the diameter of micro EDM drilling holes can be as small as φ0.02mm). Microscopic EDM can manufacture micromechanical parts such as microshafts and gears.

Composite Machining:Integrating two or more processes (such as milling + laser, turning + grinding) on a single equipment to complete multi-process machining with a single clamping is a key trend in improving the overall accuracy of complex parts and reducing turnaround time.

Anchor of Quality: “Zero Tolerance” Control of Precision and Surface

Precision Measurement:The lifeline of precision machining.

Coordinate Measuring Machine (CMM):High-end models with accuracy up to (0.6 + L/600) μm and ultra-high precision trigger or scanning probes are at the heart of complex geometries and position tolerance measurements.

Optical measurement (imager, white light interferometer, confocal microscope) :Non-contact measurement, good at nanoscale measurement of 2D size, contour and microscopic surface topography (roughness, step height).

Roundness/Cylindrical Meter:Specially designed for the analysis of shape errors (roundness, cylindricality) of precision shaft parts, with an accuracy of up to the sub-micron level.

Surface Roughness Meter: Contact (probe type) and non-contact (optical) coexist, providing key surface parameters such as Ra, Rz, Rq, Sa, Sz, etc.

Environmental control:Temperature fluctuations (usually required ± 0.1°C), vibration isolation, and cleanliness are the basic conditions to ensure the stable operation and measurement accuracy of high-end equipment.

Materials Science and Heat Treatment:Understanding material properties (such as work hardening tendency, coefficient of thermal expansion, heat treatment deformation law) is crucial for formulating rational processes and ensuring final accuracy. Precision parts often need to be stabilized (such as cryogenic treatment, aging treatment) to release stress.

Intelligent Future: Integration, Intelligence and Green

Automation and Flexible Manufacturing Unit (FMC/FMS):Flexible production line integrating robots, automatic inspection, and AGV logistics to meet the needs of efficient production of multi-variety and low-batch precision parts.

Digital twin and virtual debugging:Simulate the entire machining process in a virtual environment, optimize process parameters, predict tool wear and potential problems, greatly shorten the trial production cycle, and reduce the risk of physical debugging.

AI-driven process monitoring and optimization:Sensors are used to collect machine vibration, spindle power, acoustic emission and other signals in real time, combined with AI algorithms for tool condition monitoring, wear prediction, and adaptive machining control, to achieve intelligent closed-loop optimization of the machining process.

On-line/on-machine measurement:Integrate the measurement system into the processing equipment to achieve the integration of processing and inspection, reduce secondary clamping errors, real-time feedback compensation, and significantly improve the first-time pass rate (FPY).

Green and Precision Manufacturing:Focus on efficient cooling (micro-lubrication MQL, low-temperature cold air), energy-saving equipment, and waste waste recycling, reducing environmental impact while pursuing precision.

Precision metalworking is an ongoing challenge at the micro and even nanoscale scale. It is not only the precise synergy of machine tools, tools and processes, but also the deep integration of material science, measurement technology, information technology and rigorous craftsmanship. From a sophisticated medical implant to the core components of an aero engine soaring in the sky, every breakthrough in precision is silently expanding the boundaries of human manufacturing capabilities and supporting our modern world of precision operation.