In the realm of manufacturing, precision and efficiency are paramount. Among the various technologies that have revolutionized the industry, Computer Numerical Control (CNC) production stands out prominently. This article delves into the basics of CNC lathe machines, the current market landscape, technological advancements, and how Rapidefficient stands out in the CNC machining market. Specifically, we will explore the duration of the CNC production cycle and the value Rapidefficient brings to the table.

Understanding CNC Lathe Machines: The Bedrock of Modern Manufacturing

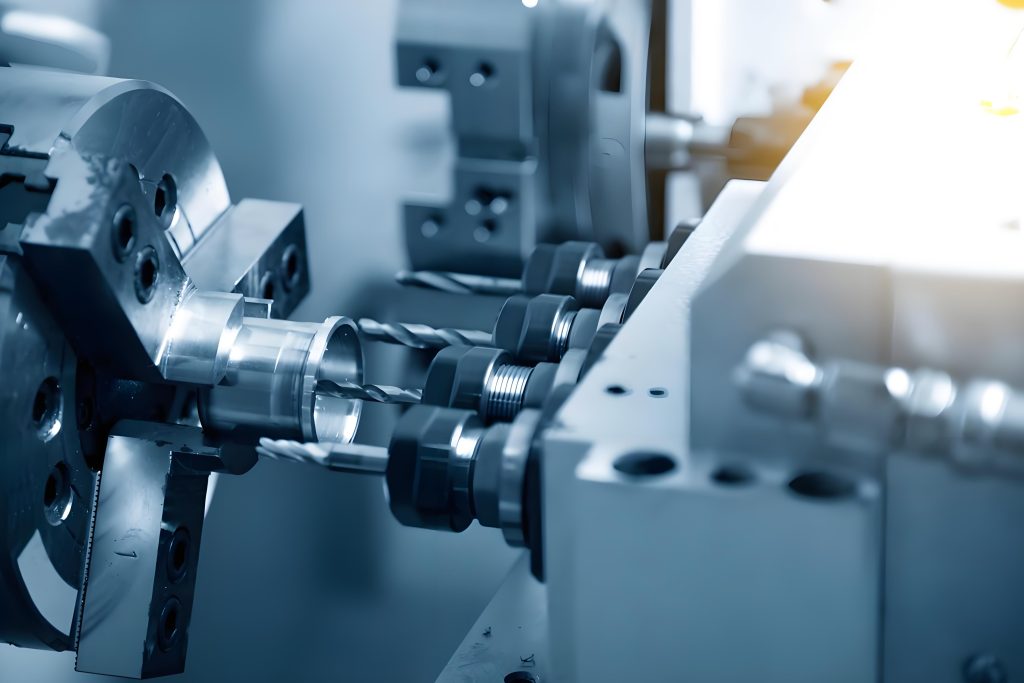

CNC lathe machines are the workhorses of the manufacturing industry. They combine the mechanical precision of traditional lathes with the computational accuracy of modern computers. By reading and interpreting numerical data from a computer program, these machines can automatically perform a variety of tasks, including cutting, drilling, and threading.

The core advantage of CNC lathes lies in their ability to achieve high levels of accuracy and repeatability. Unlike manual lathes, which rely on the skill and experience of the operator, CNC lathes eliminate human error and ensure consistent results. This makes them ideal for producing complex parts and components with tight tolerances.

Market Landscape: The Rise of CNC Production

The global CNC machine tools market has been experiencing steady growth over the past few years. This growth is fueled by several factors, including the increasing demand for precision-engineered products, advancements in technology, and the need for automation in manufacturing processes.

In particular, the automotive, aerospace, and medical industries have been significant drivers of this growth. These industries require parts and components that meet stringent quality standards and can withstand extreme conditions. CNC machines are well-suited to meet these demands, offering unparalleled precision and reliability.

Technological Innovations: Shaping the Future of CNC Production

The CNC industry is constantly evolving, driven by technological innovations that enhance the capabilities and efficiency of these machines. Here are some of the key trends shaping the future of CNC production:

Multi-Axis Machining: Modern CNC lathes are increasingly capable of multi-axis machining, allowing them to perform complex operations in a single setup. This reduces the need for secondary operations and shortens the production cycle.

High-Speed Cutting: Advances in cutting tool materials and machine dynamics have enabled higher cutting speeds, which translate to shorter cycle times and increased productivity.

Automation and Integration: The integration of robotics, sensors, and other automation technologies is transforming CNC production. These technologies enable lights-out manufacturing, where machines can operate continuously without human intervention.

Software Advancements: The development of advanced CAD/CAM software has made it easier to design and program CNC machines. These software tools offer intuitive interfaces, powerful simulation capabilities, and seamless integration with other manufacturing systems.

Rapidefficient in the CNC Production Market: A Value-Driven Approach

Rapidefficient is a leading provider of CNC production services, known for its commitment to quality, efficiency, and customer satisfaction. With a focus on aluminum processing, Rapidefficient offers a range of services that cater to the needs of various industries.

The Rapidefficient Production Cycle: Efficiency at Its Core

The production cycle at Rapidefficient is designed to maximize efficiency and minimize downtime. Here’s a closer look at the key stages of the production cycle:

Design and Programming: Customers provide Rapidefficient with their design specifications, which are then translated into a CNC program using advanced CAD/CAM software. This stage ensures that the machine is programmed correctly and is ready to produce the desired parts.

Material Preparation: The raw aluminum material is cut to size and prepared for machining. This may involve operations such as deburring, cleaning, and clamping.

Machining: The prepared material is loaded into the CNC lathe, and the machine begins to cut the part according to the programmed instructions. This stage may involve multiple passes, depending on the complexity of the part.

Inspection and Quality Control: Once the machining process is complete, the parts are inspected for quality and accuracy. This may involve visual inspection, dimensional measurement, and functional testing.

Packaging and Shipping: The finished parts are packaged securely and shipped to the customer. Rapidefficient offers flexible shipping options to meet the needs of its clients.

The entire production cycle at Rapidefficient is optimized for speed and accuracy. By leveraging advanced technology and a highly skilled workforce, Rapidefficient is able to deliver high-quality parts in a fraction of the time it would take traditional manufacturing methods.

The Rapidefficient Advantage: Quality, Efficiency, and Flexibility

Rapidefficient stands out in the CNC production market due to its commitment to quality, efficiency, and flexibility. Here are some of the key advantages that Rapidefficient offers:

Precision and Accuracy: With state-of-the-art CNC machines and advanced software, Rapidefficient is able to achieve unparalleled precision and accuracy in its parts.

Short Lead Times: Rapidefficient’s optimized production cycle allows it to deliver parts quickly, even in high volumes. This makes it an ideal partner for businesses that need to get their products to market fast.

Customizable Solutions: Rapidefficient offers a range of customizable solutions to meet the unique needs of its clients. Whether it’s a one-off prototype or a large-scale production run, Rapidefficient can provide a tailored solution that fits the bill.

Competitive Pricing: By leveraging economies of scale and efficient production processes, Rapidefficient is able to offer competitive pricing without compromising on quality.

The Future of Rapidefficient: Continuous Improvement and Innovation

Rapidefficient is committed to continuous improvement and innovation. The company regularly invests in new technology and training for its workforce to stay ahead of the curve. This ensures that Rapidefficient remains a leader in the CNC production market, offering cutting-edge solutions to its clients.

As the manufacturing industry continues to evolve, Rapidefficient is poised to play a pivotal role in shaping its future. By embracing technological advancements and staying focused on customer needs, Rapidefficient is well-positioned to deliver even greater value to its clients.

Conclusion: Rapidefficient – Your Trusted Partner in CNC Production

In conclusion, Rapidefficient is a leading provider of CNC production services that offers a range of advantages to its clients. With a focus on quality, efficiency, and flexibility, Rapidefficient is able to deliver high-quality parts in a fraction of the time it would take traditional manufacturing methods.

The production cycle at Rapidefficient is optimized for speed and accuracy, leveraging advanced technology and a highly skilled workforce. This allows Rapidefficient to offer short lead times, customizable solutions, and competitive pricing without compromising on quality.

As the manufacturing industry continues to evolve, Rapidefficient remains committed to continuous improvement and innovation. By staying ahead of the curve, Rapidefficient is poised to deliver even greater value to its clients in the future.

If you’re looking for a trusted partner in CNC production, look no further than Rapidefficient. With a proven track record of delivering high-quality parts on time and within budget, Rapidefficient is the ideal choice for businesses that need to get their products to market fast.

About Rapidefficient: Your Expert in CNC Aluminum Processing

Rapidefficient is a leading provider of CNC production services, specializing in aluminum processing. With a focus on quality, efficiency, and customer satisfaction, Rapidefficient offers a range of customizable solutions to meet the unique needs of its clients.

Our team of highly skilled professionals is dedicated to delivering the highest quality parts in the shortest possible time. We leverage advanced technology and a commitment to continuous improvement to stay ahead of the curve and deliver unparalleled value to our clients.

To learn more about Rapidefficient and our range of services, please visit our website or contact us directly. We look forward to working with you to bring your next project to life.