In the high-tech world of semiconductor manufacturing, precision is everything. Every component, from the tiniest wafer to the largest processing machine, must be manufactured with utmost accuracy to ensure reliability and performance. This is where semiconductor bearing parts play a crucial role. These components are essential for maintaining the stability and precision of semiconductor manufacturing equipment, and their production requires specialized precision processing plants.

The Importance of Precision in Semiconductor Bearings

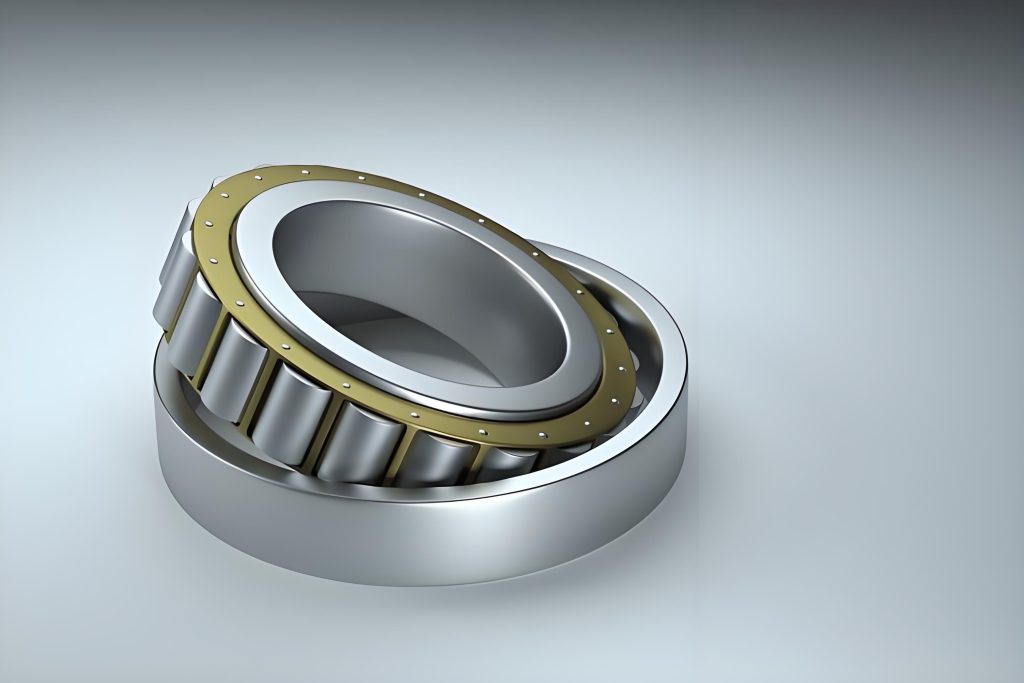

Semiconductor manufacturing involves highly sensitive processes such as lithography, chemical vapor deposition, and ion implantation. These processes require machinery that operates with extreme precision and stability. Bearings in this context must be able to withstand high speeds, maintain accuracy, and resist corrosion from harsh chemicals. Companies like NYZ and Schatz specialize in producing thin-section bearings and other precision components that meet these stringent requirements.

Key Features of Semiconductor Bearings

Precision bearings for semiconductor applications often feature:

High-precision running accuracy to ensure consistent performance.

Corrosion-resistant materials and precision seals to maintain cleanliness and reliability.

Customizable designs to fit specific equipment needs, including thin-section, angular contact, and hybrid ceramic bearings.

Precision Processing Techniques

The production of semiconductor bearing parts involves several advanced CNC machining techniques:

CNC Milling and Turning: These processes allow for the creation of complex geometries and tight tolerances, essential for high-precision bearings.

Electrical Discharge Machining (EDM): This technique is used for creating intricate shapes and achieving high precision in hard materials.

Wire EDM: Ideal for producing thin and complex parts with high accuracy.

Challenges and Solutions in Precision Machining

Producing semiconductor bearing parts presents several challenges, including the need for high precision, complex geometries, and the integration of advanced materials. Solutions include:

Investing in meticulous fixture design to ensure secure workholding.

Implementing comprehensive quality control plans with advanced measurement equipment.

Utilizing modular fixtures and advanced workholding solutions for versatility.

The Value of Rapidefficient in CNC Machining

In the competitive CNC machining market, rapidefficient stands out as a leader in providing rapid and efficient solutions for CNC aluminum processing. Their expertise in precision machining ensures that clients receive high-quality parts with quick turnaround times. Whether you need custom components for semiconductor equipment or intricate parts for other high-tech applications, rapidefficient has the technology and expertise to meet your needs.

Conclusion

Precision machining is a critical process in the production of semiconductor bearing parts, ensuring that these components meet the high standards required for semiconductor manufacturing. Advanced techniques and specialized tooling allow manufacturers to overcome the challenges of producing complex and intricate parts. Companies like rapidefficient are at the forefront of this trend, offering reliable and efficient solutions to meet the demands of the modern semiconductor industry.

About Rapidefficient

Rapidefficient is a leading provider of CNC machining services, specializing in aluminum and other precision components. Their commitment to quality and efficiency makes them a trusted partner for companies seeking reliable manufacturing solutions. Whether you need custom components or large-scale production, rapidefficient delivers high-quality parts with rapid turnaround times.