There are various forms of precision CNC machining to meet the processing needs of different workpieces and materials. The following are some common forms of precision CNC machining:

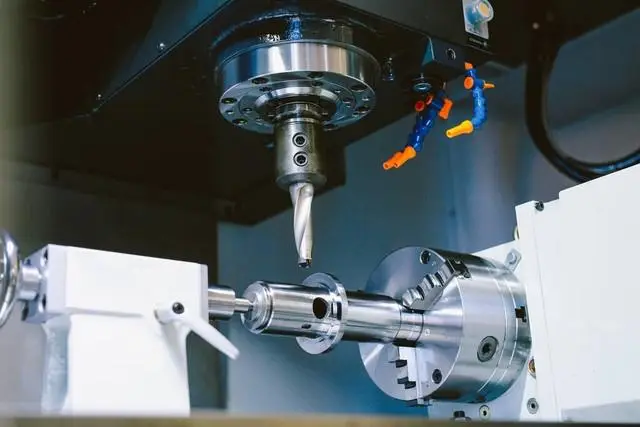

Milling: This is a common method in precision CNC machining. The cutting tool makes a rotational motion and the workpiece and the cutting tool make a linear feed. Milling can continuously cut off a certain amount of material and is suitable for machining various planes, curved surfaces and grooves.

Turning: Turning mainly uses a rotating lathe and tool to cut the workpiece. It can machine various rotating surfaces such as outer circles, inner circles, end faces, threads, grooves, etc.

Grinding: Grinding is a method of removing metal by using a grinding wheel called a grinding wheel. After grinding, the workpiece size is accurate and smooth, which is suitable for the machining of high-precision parts.

Drilling: Drilling is mainly used to drill holes in the workpiece. The drilling machine can not only perform drilling operations, but also other processing, such as reaming, reaming, countersinking and tapping.

Laser machining: CNC laser machining uses a highly focused laser beam to precisely cut, slice, or engrave materials. The laser heats the material and melts or vaporizes it, creating a cut in the material.

Electrodischarge machining (EDM): EDM uses highly controlled electric sparks to machine materials into the desired shape. It is often used to create precise micro-holes, slots, tapered or angled features in components or workpieces.

Plasma cutting: CNC plasma cutting machines use plasma arcs as heat sources to form high-temperature, high-speed plasma streams by compressing the arc to achieve cutting of materials.

There are also precision CNC machining forms such as wire cutting and water jet cutting. These machining forms have their own characteristics, and the appropriate machining method can be selected according to the material, shape, size, and precision requirements of the workpiece.