Sheet metal processing is a versatile and widely-used process in modern manufacturing. It offers numerous benefits, making it essential in industries like automotive, construction, electronics, and aerospace. This article will explore the key advantages of sheet metal fabrication and why businesses rely on it to produce durable, cost-effective products.

Durability and Strength

One of the most significant advantages of sheet metal processing is its durability. Fabricated sheet metal products can withstand harsh conditions, including extreme temperatures, pressure, and environmental exposure. Metals like steel, aluminum, and copper offer excellent resistance to corrosion and wear. As a result, products made from sheet metal last longer and require less maintenance.

In industries like automotive and aerospace, strength is critical. Sheet metal provides the structural integrity needed for vehicles, aircraft, and heavy machinery. This strength ensures that components remain reliable, even under stress. Therefore, sheet metal is ideal for producing parts that must endure rigorous conditions.

High Precision and Accuracy

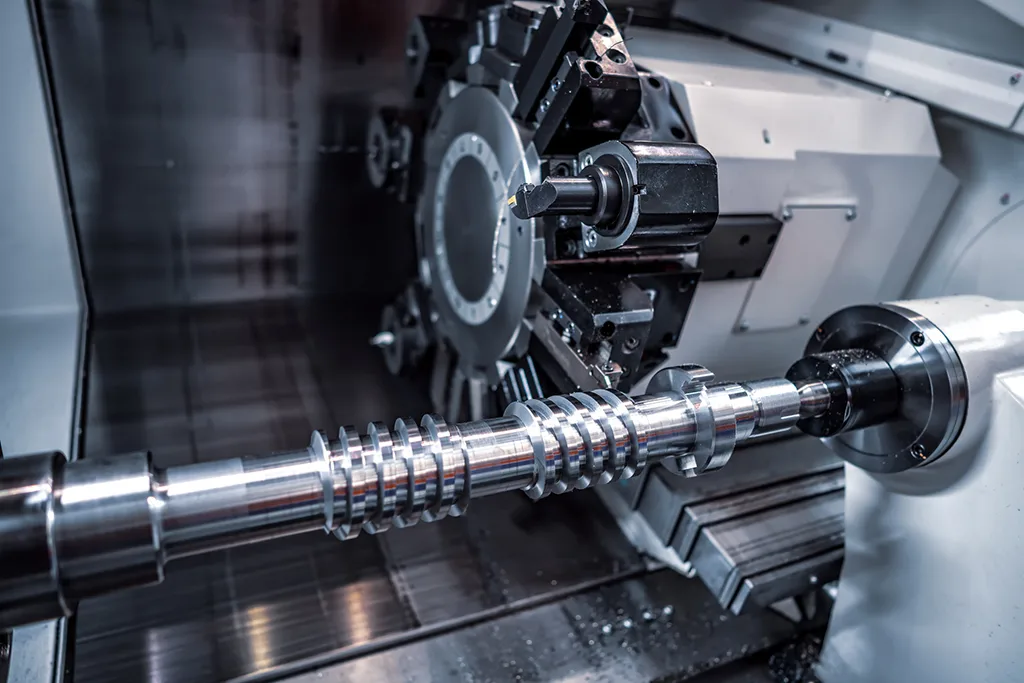

Sheet metal processing also excels in precision. Fabricators use advanced tools like laser cutters, CNC machines, and press brakes to create parts with exact measurements. These tools ensure that each piece is produced with a high level of accuracy. As a result, manufacturers can maintain consistent quality, which is essential for mass production.

In addition, modern technology like computer-aided design (CAD) software enhances precision. By designing parts digitally, fabricators can avoid errors and minimize waste. This capability makes sheet metal processing perfect for industries requiring tight tolerances, such as electronics and medical devices.

Cost-Effectiveness

Another key benefit of sheet metal processing is its cost-effectiveness. The process is efficient, particularly for large production runs. Automated equipment speeds up production, reducing labor costs and improving overall efficiency. Moreover, the availability of metals like aluminum and steel keeps material costs low.

For businesses, the cost savings associated with sheet metal processing can be significant. Producing durable, high-quality parts at a lower cost allows companies to remain competitive in their markets. In the long run, this affordability makes sheet metal processing a smart choice for manufacturing.

Flexibility in Design

Sheet metal processing offers remarkable flexibility when it comes to design. The process allows for various shapes, sizes, and complexities in products. Manufacturers can create custom parts tailored to specific needs. Whether it’s a simple bracket or a complex structural component, fabricators can adjust the process to suit the project.

This flexibility is particularly useful in industries like construction, where customized solutions are often required. Sheet metal can be formed, cut, and assembled into nearly any design. This adaptability helps businesses meet diverse client needs and take on unique projects.

Quick Turnaround Times

Efficiency is another major advantage of sheet metal processing. The process enables quick production, particularly with the use of automation and advanced machinery. Tools like laser cutters and CNC machines can rapidly produce parts with minimal human intervention. This speed reduces lead times, allowing businesses to meet tight deadlines.

Moreover, sheet metal processing reduces the time needed for prototyping. Fabricators can quickly produce prototypes for testing before committing to full production. This rapid prototyping helps businesses bring products to market faster, giving them a competitive edge.

Sustainability and Environmental Benefits

Sustainability is becoming increasingly important in manufacturing, and sheet metal processing supports this goal. Many metals used in the process, such as aluminum and steel, are recyclable. Businesses can reuse these materials, reducing waste and minimizing their environmental impact.

Additionally, the precision of sheet metal processing reduces material waste during production. By cutting parts with exact measurements, fabricators maximize material usage. This efficiency helps conserve resources and lower production costs while supporting eco-friendly practices.

Low Maintenance Requirements

Products made from sheet metal often require minimal maintenance. Their resistance to corrosion, wear, and environmental factors makes them easy to maintain. This durability reduces the need for frequent repairs or replacements, saving businesses time and money in the long run.

For industries that operate in harsh conditions, such as oil and gas or construction, low-maintenance equipment is critical. Sheet metal processing ensures that parts remain functional for extended periods, even with little upkeep.

Conclusion

In summary, sheet metal processing offers numerous advantages that make it an essential process in modern manufacturing. Its durability, precision, cost-effectiveness, and flexibility give businesses the tools they need to produce high-quality products efficiently. Additionally, quick turnaround times and sustainability make sheet metal fabrication a smart choice for industries aiming to stay competitive and eco-friendly. As technology advances, sheet metal processing will continue to be a reliable solution for manufacturing durable and versatile products.