Introduction

In today’s competitive manufacturing landscape, precision and versatility are crucial. Three axis CNC machine engraving offers a solution that combines accuracy, speed, and flexibility. This article will delve into the benefits of three axis CNC machine engraving, focusing on how Rapidefficient stands out as a leading provider of these services.

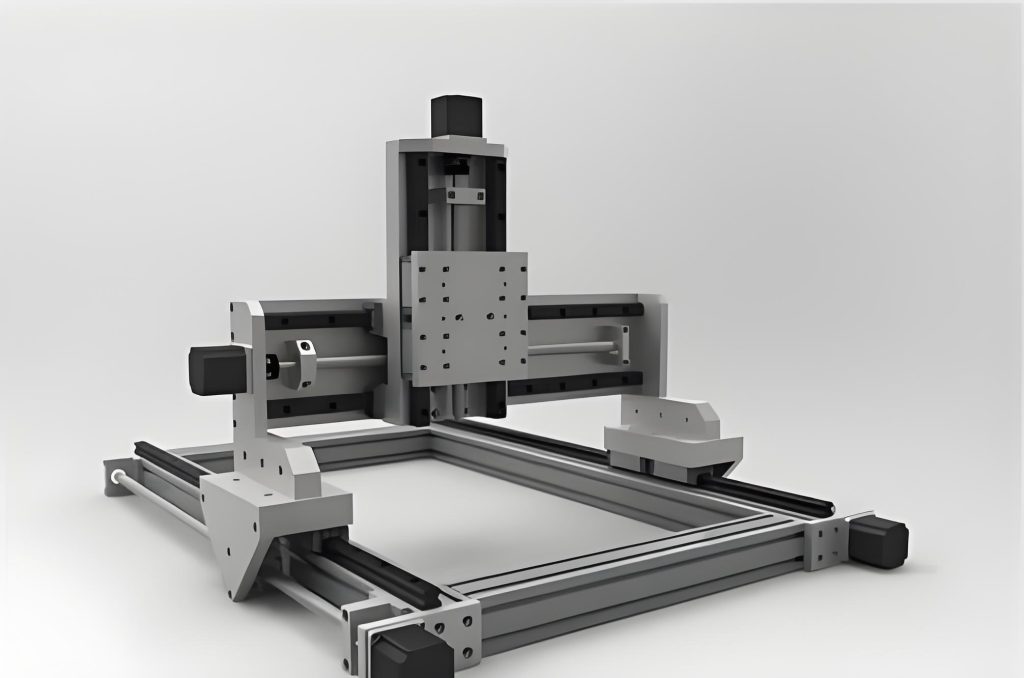

What is Three Axis CNC Machine Engraving?

Three axis CNC machine engraving involves using computer-controlled machines to carve detailed designs into various materials. These machines move along three axes—X, Y, and Z—allowing for precise control over the depth and position of the engraving. The process includes several steps:

- Design: Engineers create detailed CAD models.

- Programming: Software translates designs into machine instructions.

- Setup: Operators prepare the machine with the correct tools and materials.

- Engraving: The machine precisely carves the design according to the program.

Key Benefits of Three Axis CNC Machine Engraving

High Precision and Detail

- Three axis CNC engraving machines can achieve tolerances within microns, ensuring intricate and accurate designs.

- Automated processes ensure that every detail is replicated consistently, reducing variability and enhancing reliability.

Increased Efficiency

- CNC machines operate continuously, increasing production capacity and reducing lead times.

- Automation minimizes human error and reduces labor costs, making the process more efficient.

Versatility and Flexibility

- Three axis CNC engraving machines can handle various materials, including metals, plastics, wood, and composites.

- The ability to switch between different designs and materials quickly makes CNC engraving suitable for both small and large-scale production.

Cost-Effective Solutions

- For small batches, three axis CNC engraving eliminates the need for expensive tooling and setup costs.

- For large batches, the high-speed and automated nature of CNC engraving reduce per-unit costs, making it cost-effective for mass production.

Applications of Three Axis CNC Machine Engraving

Three axis CNC machine engraving finds applications across numerous industries, including:

Aerospace

- Instrument Panels: Detailed engravings for instrument panels in aircraft.

- Aircraft Components: Engraved markings for critical components like landing gear struts and hydraulic systems.

Automotive

- Interior Trim: Customized engravings for dashboard and interior trim pieces.

- Badges and Logos: Precise engraving of brand logos and badges on vehicles.

Electronics

- Circuit Boards: Fine engraving for circuit boards and electronic enclosures.

- Control Panels: Detailed engravings for control panels and user interfaces.

Medical Devices

- Surgical Instruments: Engraved markings for surgical instruments and medical devices.

- Prosthetics: Personalized engravings for prosthetic devices.

Consumer Goods

- Jewelry: Intricate engravings for custom jewelry pieces.

- Home Decor: Custom engravings for home decor items like picture frames and wall art.

Why Choose Rapidefficient for Your Three Axis CNC Machine Engraving Needs?

Rapidefficient is a trusted name in CNC machine engraving, offering unparalleled precision and efficiency. Here’s why you should choose us:

Advanced Technology and Equipment

- We invest in state-of-the-art three axis CNC engraving machines and software, ensuring the highest level of precision and efficiency.

- Our equipment includes multi-axis CNC engraving machines capable of handling complex geometries and tight tolerances.

Experienced and Skilled Team

- Our team of experienced engineers and technicians bring years of expertise to every project, ensuring that your engravings are manufactured to the highest standards.

- We provide technical support and consultation to help you optimize your designs and processes.

Rapid Turnaround Times

- With our efficient processes and 24/7 operation, we can deliver your engravings quickly, without compromising on quality.

- We offer expedited services for urgent orders, ensuring that you meet your deadlines.

Custom Solutions and Flexibility

- Whether you need a single prototype or a large production run, Rapidefficient can tailor its services to meet your specific needs.

- We work closely with you to understand your requirements and provide customized solutions.

Quality Assurance and Certifications

- Rapidefficient adheres to strict quality control measures, ensuring that every engraving meets the highest industry standards.

- We are ISO 9001 certified, providing you with the assurance of consistent quality and reliability.

Case Studies: Success Stories with Rapidefficient

Aerospace Component Manufacturer

A leading aerospace company needed detailed engravings for their new aircraft model. Rapidefficient delivered the engravings within a tight deadline, meeting all quality and performance requirements. The collaboration resulted in a successful product launch and enhanced customer satisfaction.

Automotive Brand

An automotive manufacturer required custom engravings for their new vehicle line. Rapidefficient provided rapid prototyping and production, helping the manufacturer meet strict branding guidelines and timelines. The partnership led to ongoing contracts and mutual trust.

Future Trends in Three Axis CNC Machine Engraving

The future of three axis CNC machine engraving is promising, with continuous advancements in technology and materials. Some key trends include:

Automation and Robotics

- Increased use of automation and robotics to further enhance efficiency and reduce labor costs.

- Integration of robotic arms for loading and unloading materials, improving throughput.

Additive Manufacturing Integration

- Combining CNC engraving with additive manufacturing (3D printing) to create hybrid manufacturing processes.

- Utilizing 3D printing for prototypes and intricate parts, followed by CNC engraving for finishing touches.

Smart Factories and Industry 4.0

- Implementation of IoT (Internet of Things) and AI (Artificial Intelligence) to optimize production and improve quality control.

- Real-time monitoring and data analytics to predict maintenance needs and prevent downtime.

Conclusion

Three axis CNC machine engraving offers unmatched precision, efficiency, and versatility, making it an essential tool for modern manufacturing. It ensures intricate and accurate designs across various industries, from aerospace to consumer goods. Rapidefficient stands out as a trusted partner, providing advanced technology, skilled expertise, and rapid turnaround times. Whether you are in the aerospace, automotive, electronics, medical, or any other industry, Rapidefficient can help you achieve your manufacturing goals.

Contact Us

Ready to experience the benefits of three axis CNC machine engraving? Contact Rapidefficient today to discuss your project and get a quote. We are here to help you unlock precision and efficiency in your manufacturing processes.

- Phone: +86 13684917827

- Email: [email protected]

- Website: www.rapidefficient.com