Introduction

As an industry expert specializing in CNC machining technology, I deeply understand the importance of small-batch customization in the production of many high-end products. Especially in precision equipment like coffee machines, the precision and quality of each part directly impacts the overall performance and user experience. Customization requirements for coffee machine parts are particularly complex, demanding both high precision and flexible production methods, which CNC machining technology perfectly addresses.

In this article, I will detail how CNC machining technology effectively solves the problem of small-batch customization of coffee machine parts, ensuring that each part meets stringent quality standards while flexibly responding to diverse customer production needs.

Challenges in Small-Batch Coffee Machine Parts Production

Coffee machine parts typically involve multiple precision components, including pump housings, filters, heating element supports, flow control valves, etc. These parts not only have high specificity in size, shape, and materials, but also often require high precision and stability for each piece produced in batches. Therefore, small-batch customization has become a common challenge for coffee machine manufacturers.

Generally, small-batch production means relatively small demand, short production cycles, and high requirements for parts. In this context, traditional production methods often face the following challenges:

- Low production efficiency: Traditional production methods often rely on manual operation or mold-based batch production, which may lead to longer production cycles and lower efficiency in small-batch scenarios, especially when order quantities are small, making it difficult to meet delivery deadlines.

- High costs: Small-batch production often makes it difficult to amortize mold-making costs, resulting in higher production costs per part.

- Cost structure pressure: In small-batch CNC manufacturing, setup, programming, and fixture preparation can account for more than 40% of total production cost, making process optimization essential for improving cost efficiency.

- Unstable quality: Traditional processing methods are easily affected by operator experience, leading to inconsistent part quality and making it difficult to guarantee that each part meets strict quality requirements.

How Does CNC Machining Solve These Problems?

Fortunately, CNC machining technology can effectively solve the above problems, making it an ideal choice for small-batch customization of coffee machine parts. Through high automation and precision control, CNC machining not only improves production efficiency but also ensures high precision and consistency of parts. Here are some key advantages of CNC machining in meeting the needs of small-batch customization of coffee machine parts:

- High precision assurance: CNC machining uses a computer numerical control system to control the machining process, achieving precise tolerances typically ranging from ±0.02 mm to ±0.005 mm, depending on machine configuration, tooling, and material properties. For high-precision components in coffee machine parts, such as pump housings and heating element brackets, CNC machining ensures that the dimensions and tolerances of each part strictly meet design requirements, avoiding errors that may occur with traditional machining methods. Material machinability also plays a key role in determining achievable tolerance and surface finish quality.

- Flexibility in Small Batch Production: Traditional production methods often require the creation of expensive molds, while CNC machining does not. By directly reading CAD design files, CNC machining can flexibly meet the needs of small-batch production, whether it’s 10 pieces, 100 pieces, or more, production can be completed in a short time. This not only significantly shortens the production cycle but also reduces production costs.

- High Repeatability and Consistency: Maintaining consistency for each part is crucial for small-batch production. One of the biggest advantages of CNC machining technology is its high repeatability. Through the automated operation of the CNC program, the precision and quality of each part are ensured to be consistent during the machining process, avoiding fluctuations that may occur in traditional manual operations.

- Realization of Complex Geometry: Coffee machine parts often have complex geometries and details. CNC machining can easily complete complex geometries and fine machining details while ensuring precision. Whether machining complex internal holes or producing casings requiring smooth surface finishes, CNC machining can precisely produce parts that meet the requirements.

Specific Applications of CNC Machining in Coffee Machine Parts Production

To more intuitively demonstrate the practical effects of CNC machining in small-batch customization of coffee machine parts, we can analyze several specific application cases:

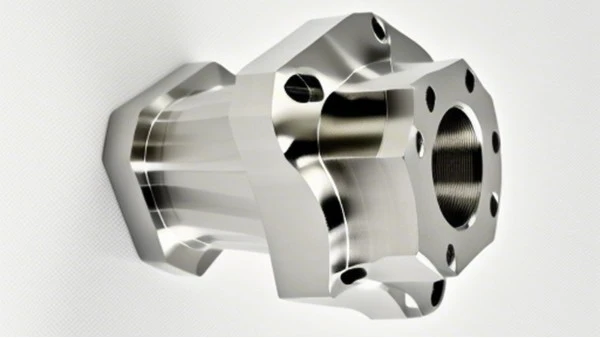

- Precision Machining of Coffee Machine Pump Housings: Coffee machine pump housings need to withstand high-pressure working environments, therefore they must possess sufficient strength and precise dimensions. CNC machining can precisely machine the pump housing’s shape according to design drawings, while simultaneously machining precise internal holes, threads, and other details in the required locations, ensuring the pump housing’s functionality and quality.

- Customization of Heating Element Brackets: The heating elements in coffee machines typically need to be fixed in specific locations to ensure their stability and safety. CNC machining can precisely manufacture brackets that meet the dimensional and strength requirements according to design specifications, ensuring consistent precision for each bracket and avoiding installation problems caused by machining errors.

- High-precision machining of filter assemblies: Filter assemblies typically involve multiple components, such as metal mesh and plastic housings. These components require precise fit to ensure stable filtration performance. CNC machining precisely controls the size and shape of each part, ensuring a perfect match and improving filter efficiency and lifespan.

- Customized flow control valves: Flow control valves are a key component in coffee machines, directly affecting the flow rate and quality of coffee. CNC machining technology precisely processes the internal and external shapes of the valve body and ensures the precision of the valve-seat fit, preventing problems such as unstable water flow or leakage.

How CNC Machining Improves Quality Control of Coffee Machine Parts

In small-batch customization of coffee machine parts, quality control is always the most critical aspect. CNC machining technology, with its high degree of automation and precise control, effectively improves the stability of quality control.

- Real-time monitoring and data feedback: CNC machining equipment is usually equipped with a real-time monitoring system that provides real-time feedback on the machining status of parts. This means that if any quality problems occur, operators can make immediate adjustments to ensure that every part meets standards.

- Parts Consistency Guarantee: In small-batch production, parts consistency is paramount. The high precision and repeatability of CNC machining ensure consistent quality and accuracy for each part throughout the manufacturing process, avoiding errors inherent in manual operation.

- Quality Traceability: Through the programmed operation of the CNC system, CNC machining records the processing data for each part, ensuring traceability of the process. This provides reliable data support for subsequent quality checks and maintenance, and helps manufacturers address potential quality issues.

How to Choose a Suitable CNC Machining Plant

For coffee machine manufacturers, choosing a suitable CNC machining plant is crucial for ensuring parts quality and delivery time. Here are some selection criteria I’ve summarized:

- Technical Strength and Equipment Level: The technical strength and equipment level of a machining plant directly impact processing quality and production efficiency. Choosing a plant with advanced equipment and an experienced technical team ensures high-precision and high-quality parts production.

- Flexibility and Response Speed: Small-batch customization typically places high demands on production cycles. Choosing a processing plant that can respond quickly and flexibly adjust production plans can help you shorten lead times and deliver on time.

- Quality Assurance System: A processing plant with a comprehensive quality assurance system can effectively control every step of the production process, ensuring that the quality of each part meets standards. It is recommended to choose manufacturers with quality certifications such as ISO certification.

- After-Sales Service: Good after-sales service can help you solve various problems encountered during use. Choosing a processing plant that can provide timely after-sales service can ensure a stable long-term partnership.

Conclusion

CNC machining technology, with its high precision, high flexibility, and high consistency, has become the ideal choice for solving the small-batch customization needs of coffee machine parts. Through CNC machining, coffee machine manufacturers can not only ensure the high quality and precision of each part, but also flexibly cope with the challenges of small-batch production, shorten production cycles, and reduce costs. When choosing a CNC machining plant, ensuring that its technical strength, quality control, and after-sales service meet your needs is key to ensuring smooth production and efficient delivery.

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience.

Its products serve industries including medical, communications, optics, drones, intelligent robotics, automotive, and office automation parts.

The company’s CNC machining centers feature four-axis, five-axis, and multi-linkage machine tools, and are equipped with precision projectors, coordinate measuring machines (CMM), spectrometers, and other advanced inspection equipment.

Machining accuracy can reach 0.01 mm, and testing accuracy can reach 0.001 mm.