Introduction

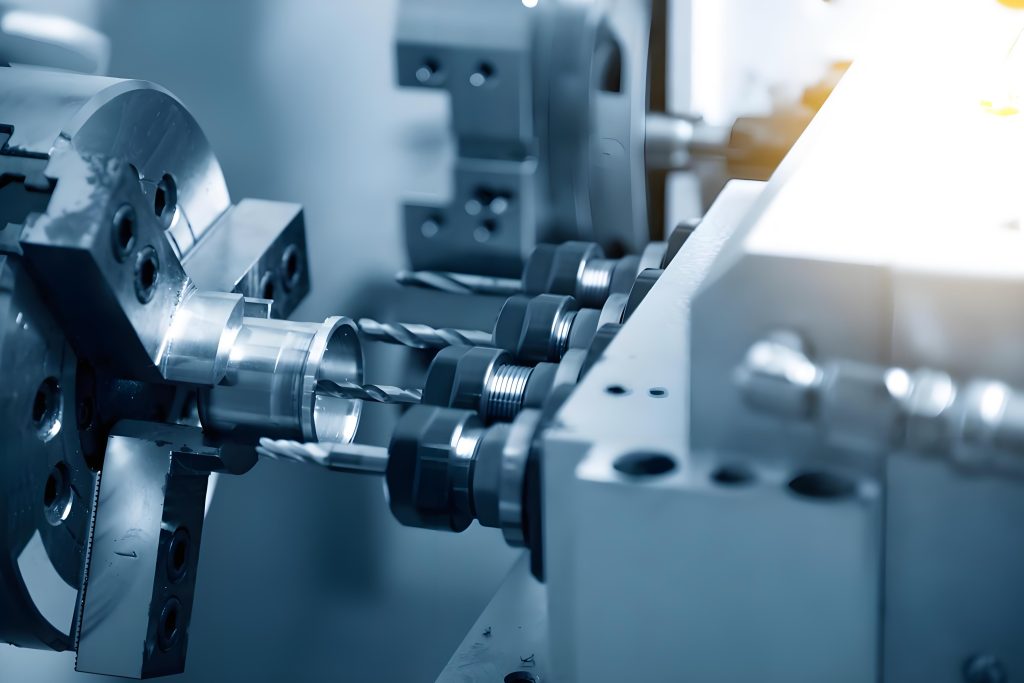

The CNC machine tool industry is a cornerstone of modern manufacturing, enabling precise and efficient production across various sectors. However, like any industry, it faces several pain points that can hinder productivity, quality, and profitability. This article will explore the major challenges in the CNC machine tool industry, discuss their impact, and highlight how Rapidefficient addresses these issues to provide superior solutions.

Key Pain Points in the CNC Machine Tool Industry

1. High Initial Investment Costs

One of the most significant barriers for companies looking to adopt CNC machining technology is the high initial investment required.

- Equipment Costs: Advanced CNC machines are expensive, often requiring substantial capital outlays.

- Training and Setup: Operators need specialized training to use these machines effectively, adding to the overall cost.

Impact: High costs can deter small and medium-sized enterprises (SMEs) from investing in CNC technology, limiting their ability to compete with larger firms.

2. Skilled Labor Shortage

Finding and retaining skilled labor is a persistent challenge in the CNC machine tool industry.

- Specialized Skills: Operating CNC machines requires knowledge of CAD/CAM software, programming, and mechanical engineering principles.

- Workforce Aging: Many experienced operators are nearing retirement, leading to a shortage of skilled workers.

Impact: A lack of skilled labor can result in lower productivity, increased errors, and longer lead times.

3. Maintenance and Downtime

CNC machines require regular maintenance to ensure optimal performance, but downtime can be costly and disruptive.

- Preventive Maintenance: Regular checks and part replacements are necessary to prevent breakdowns.

- Unplanned Downtime: Unexpected failures can halt production, causing delays and additional expenses.

Impact: Frequent maintenance and unexpected downtime can significantly reduce operational efficiency and increase costs.

4. Material Waste and Inefficiency

Material waste is a common issue in CNC machining, particularly when dealing with complex geometries and tight tolerances.

- Subtractive Manufacturing: Traditional CNC processes involve removing material, which can lead to significant waste.

- Inefficient Toolpaths: Poorly optimized toolpaths can result in unnecessary material removal and extended machining times.

Impact: High levels of material waste and inefficiency can increase production costs and environmental impact.

5. Quality Control and Consistency

Ensuring consistent quality across all produced parts is critical but challenging.

- Precision Requirements: Meeting tight tolerances and surface finish requirements demands meticulous attention to detail.

- Quality Assurance Systems: Implementing robust quality control systems is essential but can be resource-intensive.

Impact: Variability in quality can lead to rework, customer dissatisfaction, and potential recalls.

6. Integration with Modern Technologies

Integrating CNC machining with emerging technologies like IoT, AI, and additive manufacturing presents both opportunities and challenges.

- Data Management: Collecting and analyzing data from multiple sources can be complex.

- Technological Adoption: Adopting new technologies requires significant investment and training.

Impact: Companies that fail to integrate modern technologies risk falling behind competitors who leverage these advancements.

Addressing the Pain Points: Solutions Offered by Rapidefficient

Rapidefficient has developed innovative solutions to address the key pain points in the CNC machine tool industry. Here’s how we help our clients overcome these challenges:

1. Cost-Effective Solutions

We offer flexible pricing models and financing options to make advanced CNC technology more accessible to SMEs.

- Leasing Programs: Leasing allows businesses to acquire CNC machines without a large upfront investment.

- Turnkey Solutions: We provide complete packages that include equipment, installation, training, and support.

2. Comprehensive Training Programs

To address the skilled labor shortage, Rapidefficient offers comprehensive training programs for operators and technicians.

- On-Site Training: Our experts conduct on-site training sessions to familiarize staff with CNC machines and software.

- Online Courses: We provide online courses and resources for ongoing education and skill development.

3. Predictive Maintenance and Monitoring

Our advanced monitoring systems help minimize downtime and optimize maintenance schedules.

- IoT Integration: IoT sensors continuously monitor machine performance and send real-time data to our cloud platform.

- Predictive Analytics: Machine learning algorithms analyze data to predict potential failures and schedule preventive maintenance.

4. Efficient Material Usage and Process Optimization

We focus on reducing material waste and improving process efficiency through advanced techniques and tools.

- Optimized Toolpaths: Our CAM software generates highly efficient toolpaths that minimize material removal and machining time.

- Additive Manufacturing: Combining CNC with additive manufacturing reduces material waste and enables the creation of complex geometries.

5. Robust Quality Control Systems

Rapidefficient implements rigorous quality control measures to ensure consistent product quality.

- Automated Inspection: Automated inspection systems check parts for defects and deviations from specifications.

- Continuous Improvement: We continually refine our processes based on feedback and data analysis to improve quality and efficiency.

6. Seamless Integration with Modern Technologies

We help clients seamlessly integrate CNC machining with emerging technologies to stay competitive.

- Smart Factory Solutions: Our smart factory solutions enable real-time monitoring, data collection, and analysis.

- AI-Powered Optimization: AI-driven tools optimize machine settings, toolpaths, and production schedules for maximum efficiency.

Case Studies: Success Stories with Rapidefficient

Aerospace Manufacturer

A leading aerospace company needed to produce high-precision components within tight deadlines. Rapidefficient provided a turnkey solution that included advanced CNC machines, comprehensive training, and predictive maintenance systems. The collaboration resulted in improved productivity, reduced downtime, and enhanced customer satisfaction.

Automotive Supplier

An automotive supplier faced challenges with material waste and inefficient toolpaths. Rapidefficient implemented optimized CAM software and introduced additive manufacturing techniques, significantly reducing material waste and production times. The partnership led to ongoing contracts and mutual trust.

Why Choose Rapidefficient for Your CNC Machining Needs?

Rapidefficient is a trusted name in the CNC machine tool industry, offering unparalleled precision and efficiency. Here’s why you should choose us:

Advanced Technology and Equipment

- We invest in state-of-the-art CNC machines and software, ensuring the highest level of precision and efficiency.

- Our equipment includes multi-axis CNC machines capable of handling complex geometries and tight tolerances.

Experienced and Skilled Team

- Our team of experienced engineers and technicians bring years of expertise to every project, ensuring that your components are manufactured to the highest standards.

- We provide technical support and consultation to help you optimize your designs and processes.

Rapid Turnaround Times

- With our efficient processes and 24/7 operation, we can deliver your components quickly, without compromising on quality.

- We offer expedited services for urgent orders, ensuring that you meet your deadlines.

Custom Solutions and Flexibility

- Whether you need a single prototype or a large production run, Rapidefficient can tailor its services to meet your specific needs.

- We work closely with you to understand your requirements and provide customized solutions.

Quality Assurance and Certifications

- Rapidefficient adheres to strict quality control measures, ensuring that every component meets the highest industry standards.

- We are ISO 9001 certified, providing you with the assurance of consistent quality and reliability.

Conclusion

The CNC machine tool industry faces several challenges, including high initial investment costs, skilled labor shortages, maintenance and downtime issues, material waste, quality control, and technological integration. By addressing these pain points with innovative solutions, Rapidefficient helps manufacturers achieve greater efficiency, precision, and competitiveness. Whether you are in the aerospace, automotive, medical, or any other industry, Rapidefficient can help you overcome these challenges and achieve your manufacturing goals.

Contact Us

Ready to experience the benefits of advanced CNC machining? Contact Rapidefficient today to discuss your project and get a quote. We are here to help you unlock precision and efficiency in your manufacturing processes.

- Phone: +86 13684917827

- Email: [email protected]

- Website: www.rapidefficient.com