Aluminum extrusions are widely used across industries, but their prices vary significantly. Whether you’re a manufacturer or a user, understanding what drives these price differences is essential. The main factors include material composition, melting and casting processes, surface treatments, and production techniques. Each of these directly affects the cost and performance of aluminum extrusions.

1: Aluminum Extrusion Material Composition

Aluminum extrusions are made from aluminum as a base material, with other metal elements added and then heated and extruded to create various types of aluminum. These alloying elements include magnesium, copper, chromium, silicon, zinc, and manganese. The type and performance of the resulting aluminum extrusions vary greatly depending on the type of alloying elements added.

Each aluminum extrusion has a different formulation, and different series of aluminum extrusions have different standards for alloying element formulations. In addition to national standards, each manufacturer develops its own internal parameters.

For example, the 6063 series aluminum profile formula requires an aluminum content of 97.35%-98.38%, a magnesium content of 0.45%-0.9%, and a silicon content of 0.2%-0.6%. The contents of other alloying elements, such as copper, chromium, and zinc, must all be less than or equal to 0.1%. Only by meeting these content ranges can the product meet national regulations.

To reduce costs, some aluminum profile manufacturers minimize the proportion of alloying elements in the formula, significantly compromising the strength and hardness of the aluminum profiles, resulting in mechanical properties that fall short of standards. Some manufacturers also add scrap aluminum or other miscellaneous materials to the raw materials, which contributes to the low price of aluminum profiles.

2: Aluminum Melting Furnace

The production process is complex. After the aluminum alloy composition is determined, it needs to be placed in a furnace for heating and casting. The furnace is crucial at this stage.

Furnaces come in a wide variety of types, including round and square furnaces, with and without chimneys, gas-fired and electric-powered, and with capacities of one and ten tons. In short, the variety is vast. The quality of aluminum extrusions produced by each type of furnace varies.

For example, furnaces with chimneys produce higher quality than those without. This is because the aluminum bars are heated by the fuel and raw materials, producing large amounts of waste gases and residue. These are usually discharged through the chimney. In furnaces without chimneys, however, these waste gases and residue have nowhere to go and must be re-discharged into the molten aluminum. The resulting aluminum extrusions contain numerous bubbles and have an uneven surface. While these low-quality extrusions are cheaper, they also suffer from poor performance and reliability.

3: Surface Treatment of Aluminum Profiles

The oxide film on the surface of extruded aluminum profiles is very thin, only 2-4μm thick, and is relatively soft, resulting in poor corrosion resistance. It easily reacts chemically with oxygen and carbon dioxide in the air to form aluminum oxide and aluminum carbonate.

To thicken the film and enhance the corrosion resistance and appearance of the aluminum profile, the aluminum profile requires surface treatment. After multiple treatments, the oxide film thickness must reach at least 10μm to meet national standards, and some even exceed the standard, reaching 12μm or more.

Depending on the model, there are many surface treatment methods for aluminum profiles, including anodizing, electrostatic powder coating, electrophoretic coating, and sandblasting. Some surface treatments, such as anodizing, are mandatory; others, such as wood grain transfer, are optional for decorative purposes.

Because surface treatments vary from simple to complex, the price of aluminum profiles with different surface treatments varies greatly. For example, aluminum profiles used in high-end decorative applications that have undergone fluorocarbon electrostatic spraying are more expensive.

To reduce production costs and increase profits, some aluminum profile manufacturers produce profiles with oxide films as thin as 4-8μm. Some even have no oxide film at all, or even pass off inferior products as genuine products, resulting in significant price discrepancies.

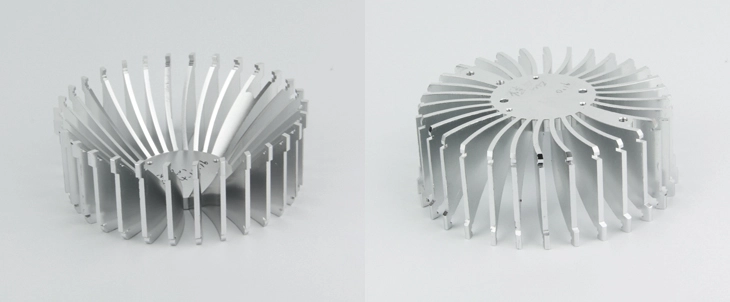

4: Aluminum Profile Production Process

Aluminum profile production involves multiple steps, starting with heating the aluminum bar, extrusion, straightening, aging, surface treatment, and packaging and warehousing. Each step has its own function and is governed by established procedures and standards.

Skipping or failing to perform any step properly can negatively impact the quality of the aluminum profile. For example, excessive impurities in the raw aluminum bar can affect the quality of the aluminum base material after extrusion. Improper control of the extrusion speed and temperature can cause yellowing and blistering on the aluminum profile surface.

The quality of the extruder can also affect the extrusion results. The aging time must be properly controlled. Artificially shortening the aging time may appear to save labor hours, but in reality, the resulting aluminum profile will be less hard. Aluminum profiles that are not aged for a sufficient time may be less expensive, but the performance may be suboptimal.

Conclusion

In summary, the price of aluminum extrusions is shaped by alloy composition, furnace quality, surface treatment, and processing methods. Each factor contributes not only to cost but also to product performance and reliability.

At Rapid Efficiency, we specialize in precision aluminum extrusion machining with strict process controls and advanced equipment. With over 40 CNC machining centers, we deliver high-accuracy parts for industries such as automotive, medical, and optics — ensuring consistent quality and value.