CNC aluminum machining is a manufacturing process that uses computer numerical control (CNC) technology to create precise aluminum parts. This process is popular in various industries, including aerospace, automotive, and electronics. It ensures high accuracy and efficiency.

Understanding CNC Machining

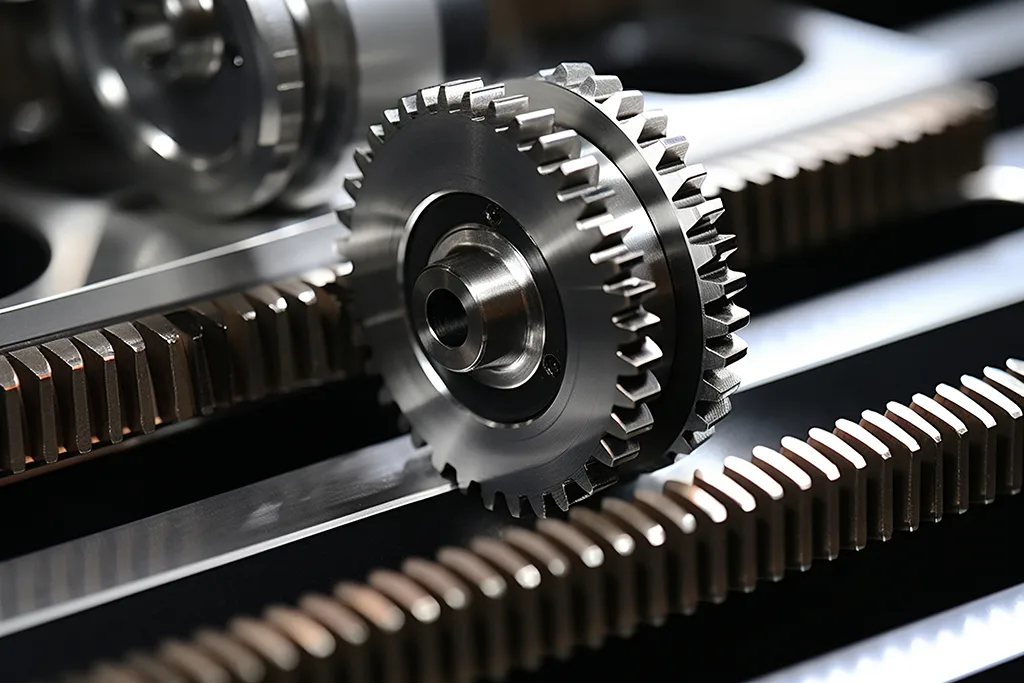

CNC machining involves using a computer to control machinery. Operators input designs into the software. The machine then cuts, drills, or shapes aluminum according to the specifications. This method offers many advantages. For example, it allows for complex designs that are difficult to achieve with manual machining.

Benefits of CNC Aluminum Machining

One of the ultimate benefits of CNC aluminum machining is precision. CNC machines can produce parts with tight tolerances. This means the parts fit together perfectly, which is crucial for many applications. Additionally, CNC machining reduces waste. The process optimizes material usage, saving costs and resources.

Another key advantage is speed. CNC machines operate quickly and consistently. They can run 24/7, which significantly shortens production times. This efficiency allows companies to meet tight deadlines. Moreover, it helps businesses respond to market demands rapidly.

Applications of CNC Aluminum Parts

CNC aluminum parts find applications across many sectors. In aerospace, they create lightweight components that enhance fuel efficiency. In the automotive industry, manufacturers use them for parts like brackets and housings. Electronics companies often utilize CNC machining for enclosures and connectors.

Furthermore, CNC machining supports prototyping. Engineers can create prototypes quickly. They can test designs before mass production. This process reduces risks and improves product quality.

Key Considerations in CNC Machining

When choosing CNC aluminum machining, several factors come into play. First, consider the material. Aluminum is lightweight and corrosion-resistant, making it ideal for many applications. However, not all aluminum alloys are the same. Each alloy has unique properties, so selecting the right one is essential.

Next, examine the design complexity. CNC machining excels at creating intricate designs. However, highly complex shapes may require specialized tools or techniques. Discussing your design with a machinist is crucial to ensure feasibility.

Finally, think about cost. CNC machining can be more expensive than traditional methods. However, the benefits often outweigh the costs. The precision and efficiency lead to long-term savings.

Choosing the Right CNC Machining Service

Selecting a CNC machining service is vital for your project’s success. Look for a company with experience in aluminum machining. They should have a solid reputation and positive reviews. Additionally, inquire about their equipment. Modern CNC machines can handle various tasks and materials.

Communication is also essential. A good machining service will discuss your needs openly. They will provide insights and suggestions to enhance your design. This collaboration can lead to better results.

Conclusion

In summary, CNC aluminum machining is a powerful manufacturing method. It offers precision, speed, and efficiency. By understanding its benefits and applications, you can make informed decisions. Whether you are in aerospace, automotive, or electronics, CNC aluminum parts can meet your needs. Remember to choose a reliable machining service to ensure the best outcomes for your projects.