What is CNC Precision Machining?

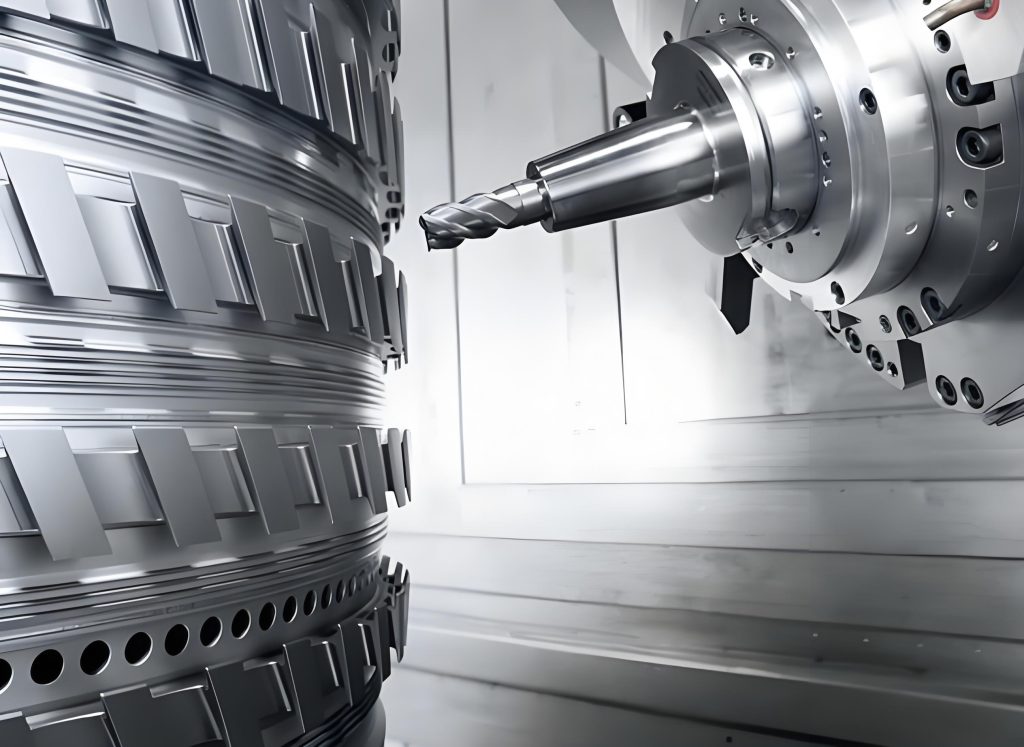

CNC precision machining is a cutting-edge manufacturing process that combines computer numerical control technology with high-precision machining operations. It is widely regarded as a crucial technique in various industries due to its ability to produce complex and accurate parts with exceptional quality.

In essence, CNC precision machining refers to the use of computer-controlled machines to perform a wide range of machining tasks. These machines are programmed with specific instructions that guide the cutting tools to shape raw materials into the desired forms. The process involves several steps, including design, programming, setup, and machining.

One of the key advantages of CNC precision machining is its high level of precision. With the ability to control the movement of cutting tools with great accuracy, it can produce parts with tolerances as low as a few micrometers. This level of precision is essential in industries such as aerospace, medical, and electronics, where even the slightest deviation can have a significant impact on the performance and reliability of the final product.

Another advantage of CNC precision machining is its efficiency. The computer-controlled nature of the process allows for rapid and repeatable production, reducing lead times and increasing productivity. Additionally, CNC machines can operate continuously, minimizing downtime and maximizing output.

The applications of CNC precision machining are vast and diverse. In the aerospace industry, it is used to manufacture components such as turbine blades, engine parts, and structural elements. These parts require extremely high precision and durability to withstand the harsh operating conditions of flight. In the medical field, CNC precision machining is employed to produce implants, surgical instruments, and diagnostic equipment. The accuracy and quality of these parts are crucial for patient safety and the effectiveness of medical procedures. In the electronics industry, CNC precision machining is used to create components such as connectors, housings, and heat sinks. The small size and complex geometries of these parts demand precise machining to ensure proper functionality.

In conclusion, CNC precision machining is a highly advanced manufacturing process that offers exceptional precision, efficiency, and versatility. It plays a vital role in numerous industries, enabling the production of complex and accurate parts that meet the demanding requirements of modern technology.

CNC machines are capable of achieving extremely high levels of precision, ensuring that parts are manufactured to exact specifications. This high precision is a crucial advantage of CNC precision machining.

Precision machining refers to a manufacturing process that aims to achieve very accurate dimensions, shapes, and surface qualities. In the context of CNC precision machining, the use of computer-controlled machines allows for a high degree of control over the cutting tools, resulting in extremely precise manufacturing.

The precision of CNC machining is often measured in micrometers, which is a very small unit of measurement. This level of precision is essential in industries such as aerospace, medical, and electronics, where even the slightest deviation from the specified dimensions can have a significant impact on the performance and reliability of the final product.

For example, in the aerospace industry, turbine blades and engine parts require extremely high precision to ensure efficient operation and safety. The tight tolerances achieved by CNC precision machining ensure that these parts fit together perfectly and can withstand the harsh operating conditions of flight.

In the medical field, implants, surgical instruments, and diagnostic equipment must be manufactured with high precision to ensure patient safety and the effectiveness of medical procedures. CNC precision machining allows for the production of these parts with the exact specifications required for proper functionality.

In the electronics industry, the small size and complex geometries of components such as connectors, housings, and heat sinks demand precise machining. The high precision of CNC machining ensures that these parts can be manufactured to meet the tight tolerances required for proper electrical performance.

In conclusion, the high precision of CNC precision machining is a key advantage that makes it an essential manufacturing process in many industries. The ability to achieve extremely accurate dimensions and shapes ensures that parts are manufactured to exact specifications, resulting in high-quality products that meet the demanding requirements of modern technology.

If you are looking for a reliable and high-quality CNC precision machining service provider, look no further than rapidefficient. With years of experience and a team of highly skilled professionals, rapidefficient offers a wide range of CNC machining services to meet your specific needs. Whether you need complex parts for the aerospace industry, medical devices, or electronics components, rapidefficient has the expertise and equipment to deliver exceptional results. Contact rapidefficient today to learn more about our services and how we can help you with your next project.

The automated nature of CNC machining allows for fast and efficient production, reducing lead times and increasing productivity.

CNC machines operate with precision and speed, ensuring a seamless production process. The automated features enable continuous operation, minimizing downtime and maximizing output. This efficiency is crucial in today’s competitive manufacturing landscape.

For instance, in industries such as aerospace, the demand for high-quality and precisely manufactured components is constant. CNC precision machining can meet these demands by quickly producing complex parts with tight tolerances. The ability to program and execute multiple operations simultaneously reduces lead times and allows for faster delivery of products.

In the medical field, the need for accurate and reliable components is essential. CNC machining can produce implants, surgical instruments, and diagnostic equipment with high precision and efficiency. The automated processes ensure consistent quality and reduce the risk of errors.

Similarly, in the electronics industry, the small size and complex geometries of components require precise machining. CNC machines can handle these requirements with ease, producing parts quickly and accurately.

The efficiency of CNC machining also extends to cost savings. By reducing lead times and increasing productivity, manufacturers can lower production costs and improve their bottom line. Additionally, the repeatability of the process ensures consistent quality, reducing waste and rework.

If you are looking for a reliable and efficient CNC precision machining service provider, look no further than rapidefficient. With state-of-the-art equipment and a team of highly skilled professionals, rapidefficient can meet all your machining needs. Contact us today to learn more about our services and how we can help you achieve your production goals.

Versatility

CNC machines exhibit remarkable versatility in both materials and part geometries. They can handle a wide range of materials, from metals like aluminum and steel to plastics and composites. This adaptability makes them suitable for diverse applications across different industries.

In terms of part geometries, CNC machines can create complex shapes and designs with precision. Whether it’s intricate curves, sharp angles, or detailed features, these machines can follow the programmed instructions precisely to produce parts that meet the specific requirements of each application.

For example, in the aerospace industry, CNC machines are used to manufacture turbine blades with complex aerodynamic shapes. The ability to handle tough materials and create precise geometries is crucial for ensuring the efficiency and safety of aircraft engines.

In the medical field, CNC precision machining is employed to produce implants and surgical instruments with specific shapes and dimensions. The versatility of CNC machines allows for the creation of customized medical devices that fit the unique anatomy of each patient.

In the electronics industry, CNC machines can produce small and intricate components with high precision. The ability to handle different materials and create complex geometries is essential for the production of connectors, housings, and heat sinks that meet the demanding requirements of modern electronic devices.

The versatility of CNC machines is also evident in their ability to handle both large and small production runs. Whether it’s a single prototype or a large batch production, CNC machines can be programmed to meet the specific needs of each project.

In conclusion, the versatility of CNC machines makes them an essential tool in modern manufacturing. Their ability to handle a wide range of materials and part geometries enables them to meet the diverse needs of different industries, from aerospace to medical to electronics. If you are looking for a reliable and versatile CNC precision machining service provider, look no further than rapidefficient. With advanced equipment and a team of highly skilled professionals, rapidefficient can handle any machining project, big or small. Contact us today to learn more about our services and how we can help you with your next project.

High-Quality Machining

Rapidefficient offers fast, high-quality CNC machining services, from single prototypes to large production runs.

CNC machines are capable of achieving extremely high levels of precision, ensuring that parts are manufactured to exact specifications. This high precision is a crucial advantage of CNC precision machining. Precision machining aims to achieve very accurate dimensions, shapes, and surface qualities. In the context of CNC precision machining, computer-controlled machines allow for a high degree of control over cutting tools, resulting in extremely precise manufacturing.

The precision of CNC machining is often measured in micrometers. This level of precision is essential in industries such as aerospace, medical, and electronics. For example, in the aerospace industry, turbine blades and engine parts require extremely high precision for efficient operation and safety. In the medical field, implants, surgical instruments, and diagnostic equipment must be manufactured with high precision for patient safety and effectiveness. In the electronics industry, small and complex components demand precise machining for proper electrical performance.

The automated nature of CNC machining allows for fast and efficient production, reducing lead times and increasing productivity. CNC machines operate with precision and speed, ensuring a seamless production process. The automated features enable continuous operation, minimizing downtime and maximizing output. This efficiency is crucial in today’s competitive manufacturing landscape.

For instance, in the aerospace industry, the demand for high-quality and precisely manufactured components is constant. CNC precision machining can meet these demands by quickly producing complex parts with tight tolerances. In the medical field, the need for accurate and reliable components is essential. CNC machining can produce implants and surgical instruments with high precision and efficiency. In the electronics industry, the small size and complex geometries of components require precise machining. CNC machines can handle these requirements with ease, producing parts quickly and accurately.

The efficiency of CNC machining also extends to cost savings. By reducing lead times and increasing productivity, manufacturers can lower production costs and improve their bottom line. Additionally, the repeatability of the process ensures consistent quality, reducing waste and rework.

Versatility

CNC machines exhibit remarkable versatility in both materials and part geometries. They can handle a wide range of materials, from metals like aluminum and steel to plastics and composites. This adaptability makes them suitable for diverse applications across different industries.

In terms of part geometries, CNC machines can create complex shapes and designs with precision. Whether it’s intricate curves, sharp angles, or detailed features, these machines can follow the programmed instructions precisely to produce parts that meet the specific requirements of each application.

For example, in the aerospace industry, CNC machines are used to manufacture turbine blades with complex aerodynamic shapes. The ability to handle tough materials and create precise geometries is crucial for ensuring the efficiency and safety of aircraft engines. In the medical field, CNC precision machining is employed to produce implants and surgical instruments with specific shapes and dimensions. The versatility of CNC machines allows for the creation of customized medical devices that fit the unique anatomy of each patient.

In the electronics industry, CNC machines can produce small and intricate components with high precision. The ability to handle different materials and create complex geometries is essential for the production of connectors, housings, and heat sinks that meet the demanding requirements of modern electronic devices.

The versatility of CNC machines is also evident in their ability to handle both large and small production runs. Whether it’s a single prototype or a large batch production, CNC machines can be programmed to meet the specific needs of each project.

In conclusion, the versatility of CNC machines makes them an essential tool in modern manufacturing. Their ability to handle a wide range of materials and part geometries enables them to meet the diverse needs of different industries, from aerospace to medical to electronics. If you are looking for a reliable and versatile CNC precision machining service provider, look no further than rapidefficient. With advanced equipment and a team of highly skilled professionals, rapidefficient can handle any machining project, big or small. Contact us today to learn more about our services and how we can help you with your next project.

Experienced Team

Rapidefficient boasts an experienced team of machinists and engineers who are dedicated to providing exceptional guidance and support throughout the entire CNC precision machining process.

This team of professionals is highly skilled and knowledgeable in the field of CNC machining. They have extensive experience working with a wide range of materials and part geometries, ensuring that every project is executed with precision and efficiency.

The machinists are experts in operating the CNC machines, ensuring that the cutting tools follow the programmed instructions precisely to achieve the desired shapes and dimensions. They are trained to handle complex machining tasks and are able to troubleshoot any issues that may arise during the process.

The engineers play a crucial role in the design and programming stages. They use advanced software to create detailed designs and generate precise machining instructions. Their expertise in engineering principles and materials science allows them to optimize the machining process for maximum efficiency and quality.

With their combined experience and expertise, the team at Rapidefficient is able to handle projects of any complexity. Whether it’s a single prototype or a large production run, they can deliver high-quality results that meet the exact specifications of the customer.

The experienced team at Rapidefficient is committed to providing excellent customer service. They work closely with customers to understand their unique needs and requirements, and provide personalized solutions that ensure customer satisfaction.

In conclusion, the experienced team at Rapidefficient is a key asset in providing high-quality CNC precision machining services. Their expertise and dedication ensure that every project is a success.

Competitive Pricing

Rapidefficient offers competitive pricing without sacrificing quality. This is a significant advantage in the CNC precision machining industry. In a market where customers are constantly looking for cost-effective solutions without compromising on the quality of the end product, Rapidefficient stands out as a reliable choice.

The company achieves competitive pricing through a combination of efficient production processes, strategic sourcing of materials, and a focus on continuous improvement. By optimizing its operations, Rapidefficient is able to reduce costs while maintaining the high level of precision and quality that its customers expect.

For example, the automated nature of CNC machining allows for fast and efficient production, reducing lead times and increasing productivity. This efficiency translates into cost savings that can be passed on to customers in the form of competitive pricing.

In addition, Rapidefficient’s experienced team of machinists and engineers is able to optimize the machining process to minimize waste and rework. This not only improves the quality of the end product but also reduces costs, further contributing to the company’s competitive pricing.

Compared to other CNC precision machining service providers, Rapidefficient offers a unique combination of quality and affordability. Whether you need a single prototype or a large production run, you can trust Rapidefficient to deliver high-quality results at a competitive price.

If you are looking for a CNC precision machining service provider that offers competitive pricing without sacrificing quality, look no further than Rapidefficient. Contact us today to learn more about our services and how we can help you with your next project.

Precision Machining for Aerospace Components

Rapidefficient has successfully delivered numerous CNC precision machining projects for aerospace components. One notable example is the production of complex turbine blades.

In this project, Rapidefficient was tasked with manufacturing turbine blades for a leading aerospace company. The blades required extremely high precision and durability to withstand the harsh operating conditions of flight.

Using state-of-the-art CNC machines, Rapidefficient’s team of highly skilled machinists and engineers programmed the machines to follow precise instructions. The materials used for these blades were carefully selected to ensure optimal performance and longevity.

The machining process involved multiple steps, including design, programming, setup, and machining. The engineers at Rapidefficient used advanced software to create detailed designs and generate precise machining instructions. The machinists then operated the CNC machines with precision and speed, ensuring a seamless production process.

The tight tolerances achieved by Rapidefficient’s CNC precision machining ensured that the turbine blades fit together perfectly and could withstand the extreme forces and temperatures encountered during flight. The high level of precision also contributed to the efficiency of the aircraft engines, reducing fuel consumption and emissions.

In addition to turbine blades, Rapidefficient has also provided CNC precision machining services for other aerospace components such as engine parts and structural elements. These parts also require high precision and durability to ensure the safety and performance of aircraft.

The success of this aerospace project is a testament to Rapidefficient’s expertise and capabilities in CNC precision machining. The company’s advanced equipment, experienced team, and commitment to quality make it a reliable choice for aerospace companies looking for high-quality machining services.

If you are in the aerospace industry and need CNC precision machining services for your components, look no further than rapidefficient. Contact us today to learn more about our services and how we can help you with your next project.

Custom Machining for Medical Devices

Rapidefficient has demonstrated its excellence in providing custom machining services for medical devices. In a recent project, a leading medical device manufacturer approached Rapidefficient for the production of specialized parts for a new diagnostic instrument.

The requirements for these parts were extremely stringent. They needed to be manufactured with high precision to ensure accurate readings and reliable performance. The materials used had to meet strict medical-grade standards to ensure patient safety.

Rapidefficient’s team of experienced machinists and engineers rose to the challenge. Using state-of-the-art CNC machines, they programmed the machines to follow precise instructions, ensuring that every cut and measurement was accurate to within micrometers.

The materials selected for the project were carefully chosen for their biocompatibility and durability. Rapidefficient’s knowledge of different materials allowed them to recommend the best options for the specific application.

The machining process involved multiple steps, including design, programming, setup, and machining. The engineers at Rapidefficient used advanced software to create detailed designs and generate precise machining instructions. The machinists then operated the CNC machines with precision and care, ensuring a seamless production process.

The result was a set of custom parts that met all the requirements of the medical device manufacturer. The high precision of the machining ensured that the parts fit together perfectly and functioned as intended. The use of quality materials and strict quality control measures ensured that the parts were safe and reliable.

This project is just one example of Rapidefficient’s capabilities in custom machining for medical devices. Whether it’s implants, surgical instruments, or diagnostic equipment, Rapidefficient has the expertise and equipment to deliver high-quality results.

If you are in the medical device industry and need custom machining services, look no further than rapidefficient. Contact us today to learn more about our services and how we can help you with your next project.

Summary of CNC Precision Machining

CNC precision machining is a highly advanced manufacturing process that combines computer numerical control technology with high-precision machining operations. It offers several key benefits that make it essential in various industries.

The high precision of CNC precision machining is a crucial advantage. CNC machines can achieve extremely accurate dimensions, often measured in micrometers. This level of precision is essential in industries such as aerospace, medical, and electronics, where even the slightest deviation can have a significant impact on the performance and reliability of the final product. For example, in the aerospace industry, turbine blades and engine parts require high precision for efficient operation and safety. In the medical field, implants, surgical instruments, and diagnostic equipment must be manufactured with precision for patient safety and effectiveness. In the electronics industry, small and complex components demand precise machining for proper electrical performance.

The automated nature of CNC machining allows for fast and efficient production. CNC machines operate with precision and speed, ensuring a seamless production process. The automated features enable continuous operation, minimizing downtime and maximizing output. This efficiency is crucial in today’s competitive manufacturing landscape. For instance, in industries like aerospace, the demand for high-quality and precisely manufactured components is constant. CNC precision machining can meet these demands by quickly producing complex parts with tight tolerances. In the medical field, the need for accurate and reliable components is essential. CNC machining can produce implants and surgical instruments with high precision and efficiency. In the electronics industry, the small size and complex geometries of components require precise machining. CNC machines can handle these requirements with ease, producing parts quickly and accurately. The efficiency of CNC machining also leads to cost savings by reducing lead times and increasing productivity. Additionally, the repeatability of the process ensures consistent quality, reducing waste and rework.

The versatility of CNC machines is another significant advantage. They can handle a wide range of materials, from metals like aluminum and steel to plastics and composites. This adaptability makes them suitable for diverse applications across different industries. In terms of part geometries, CNC machines can create complex shapes and designs with precision. Whether it’s intricate curves, sharp angles, or detailed features, these machines can follow the programmed instructions precisely to produce parts that meet the specific requirements of each application. For example, in the aerospace industry, CNC machines are used to manufacture turbine blades with complex aerodynamic shapes. In the medical field, they are employed to produce implants and surgical instruments with specific shapes and dimensions. In the electronics industry, CNC machines can produce small and intricate components with high precision. The versatility of CNC machines is also evident in their ability to handle both large and small production runs.

Rapidefficient offers fast, high-quality CNC machining services. The company’s experienced team of machinists and engineers is dedicated to providing exceptional guidance and support throughout the entire CNC precision machining process. They are highly skilled and knowledgeable in the field of CNC machining, ensuring that every project is executed with precision and efficiency. Rapidefficient also offers competitive pricing without sacrificing quality. The company achieves this through efficient production processes, strategic sourcing of materials, and a focus on continuous improvement.

In conclusion, CNC precision machining is a vital manufacturing process that offers high precision, efficiency, and versatility. Rapidefficient is a reliable and high-quality CNC precision machining service provider that can meet the diverse needs of different industries. Whether it’s aerospace components, medical devices, or electronics components, Rapidefficient has the expertise and equipment to deliver exceptional results. Contact rapidefficient today to learn more about our services and how we can help you with your next project.

Recommendation for Rapidefficient

If you are in search of a top-notch CNC machining service provider, Rapidefficient is an excellent choice. With its years of experience and a team of highly skilled professionals, Rapidefficient offers a comprehensive range of services that are designed to meet the diverse needs of various industries.

Whether you require CNC precision machining for aerospace components, custom machining for medical devices, or high-quality machining for electronics components, Rapidefficient has the expertise and equipment to deliver exceptional results. The company’s advanced CNC machines are capable of achieving extremely high levels of precision, ensuring that parts are manufactured to exact specifications.

The automated nature of Rapidefficient’s CNC machining processes allows for fast and efficient production, reducing lead times and increasing productivity. This efficiency is crucial in today’s competitive manufacturing landscape. Additionally, Rapidefficient’s experienced team of machinists and engineers is dedicated to providing exceptional guidance and support throughout the entire CNC precision machining process.

Rapidefficient also offers competitive pricing without sacrificing quality. The company achieves this through efficient production processes, strategic sourcing of materials, and a focus on continuous improvement. Whether you need a single prototype or a large production run, you can trust Rapidefficient to deliver high-quality results at a competitive price.

In conclusion, if you are looking for a reliable and high-quality CNC precision machining service provider, look no further than rapidefficient. Contact us today to learn more about our services and how we can help you with your next project.