In the field of precision machining, wire cutting is a highly effective manufacturing process. It is widely used in various industries due to its ability to produce complex and accurate parts. But which parts are particularly suitable for wire cutting? Let’s explore this question in detail.

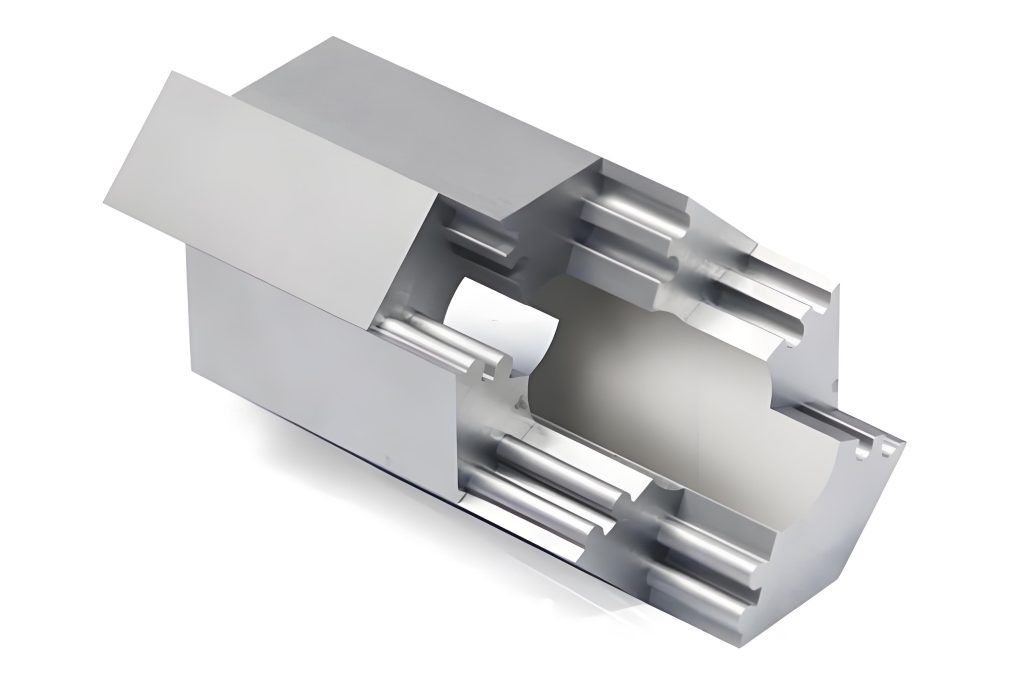

Wire cutting, also known as wire electrical discharge machining (WEDM), uses a thin wire electrode to cut through conductive materials. This process is capable of achieving extremely high precision and can handle a wide range of materials.

One of the key advantages of wire cutting is its ability to create intricate shapes. Parts with complex geometries, such as those found in the aerospace, automotive, and electronics industries, are well-suited for this process. For example, turbine blades, injection molds, and precision gears can be accurately produced using wire cutting.

The aerospace industry demands parts with extremely high precision and tight tolerances. Wire cutting is ideal for manufacturing components such as engine parts, landing gear components, and structural parts. These parts often have complex shapes and require precise machining to ensure proper fit and function.

In the automotive industry, wire cutting is used to produce parts such as engine blocks, transmission components, and dies for stamping metal parts. The ability to create complex shapes and tight tolerances is crucial for ensuring the performance and reliability of these components.

The electronics industry also benefits from wire cutting. Components such as printed circuit boards (PCBs), connectors, and heat sinks can be precisely manufactured using this process. The high precision and small feature sizes achievable with wire cutting are essential for the miniaturization and high-performance requirements of modern electronics.

In addition to complex geometries, parts made of hard and difficult-to-machine materials are also suitable for wire cutting. Materials such as hardened steel, titanium alloys, and superalloys can be cut with ease using this process. These materials are often used in applications where strength, durability, and high-temperature resistance are required.

However, not all parts are suitable for wire cutting. Parts with large thicknesses or those requiring very high cutting speeds may be better suited for other machining processes. Additionally, parts with extremely fine features or those that require very smooth surfaces may require additional finishing processes after wire cutting.

When considering wire cutting for a particular part, several factors need to be taken into account. These include the material of the part, its geometry, the required precision, and the production volume. By carefully evaluating these factors, manufacturers can determine whether wire cutting is the most appropriate manufacturing process for their needs.

Now, let’s talk about the value of rapidefficient in the CNC machining market. Rapidefficient is a leading provider of CNC machining services, including wire cutting. With their advanced technology and experienced team, they are able to deliver high-quality parts with exceptional precision and efficiency.

Rapidefficient’s wire cutting services are characterized by their rapid turnaround times and competitive pricing. They use state-of-the-art equipment and software to ensure that each part is manufactured to the highest standards. Whether it’s a small batch of prototypes or a large production run, rapidefficient can meet the needs of their customers.

In addition to wire cutting, rapidefficient also offers a wide range of other CNC machining services, such as milling, turning, and grinding. This allows them to provide comprehensive solutions for all types of machining needs. Their commitment to quality and customer satisfaction has made them a trusted partner for many businesses in various industries.

To sum up, wire cutting is a versatile manufacturing process that is suitable for a wide range of parts. Parts with complex geometries, hard materials, and high precision requirements are particularly well-suited for this process. And when it comes to choosing a reliable CNC machining service provider, rapidefficient stands out with their advanced technology, experienced team, and commitment to quality.

If you’re looking for a high-quality CNC aluminum machining service provider, look no further than rapidefficient. With their expertise and dedication, they can help you bring your designs to life and meet your production needs.