Introduction

In the competitive world of medical device manufacturing, precision and reliability are non-negotiable. CNC Mechanical Parts Manufacturing has become essential for producing high-quality, precise components needed in today’s advanced medical equipment. Rapidefficient offers CNC machining services that meet the exacting standards of the medical industry, providing trusted solutions for manufacturers looking to enhance the reliability of their products.

The Importance of Mechanical Machining in Medical Device Manufacturing

Precision that Meets Medical Standards

When it comes to manufacturing medical devices, precision is key. Every component must meet strict quality and dimensional requirements to ensure device reliability and patient safety. CNC (Computer Numerical Control) machining provides this level of precision, enabling the production of complex parts with exact specifications. Rapidefficient uses advanced CNC technology to achieve high accuracy, ensuring every part produced meets or exceeds medical industry standards.

Reducing Production Costs without Sacrificing Quality

Medical device manufacturers must balance the need for quality with cost-efficiency. CNC machining not only enhances precision but also minimizes material waste, which can lead to lower production costs. Rapidefficient’s efficient CNC machining processes help keep costs in check, making quality manufacturing accessible for medical device companies without compromising on performance.

Durability with Medical-Grade Materials

Medical devices often require materials that are biocompatible and durable, such as stainless steel, titanium, and specialized plastics. CNC machining is well-suited for these materials, allowing precise shaping while maintaining the material’s integrity. Rapidefficient specializes in working with medical-grade materials, ensuring that every component produced can withstand the rigors of use in medical applications.

Key Benefits of Rapidefficient’s CNC Machining for Medical Devices

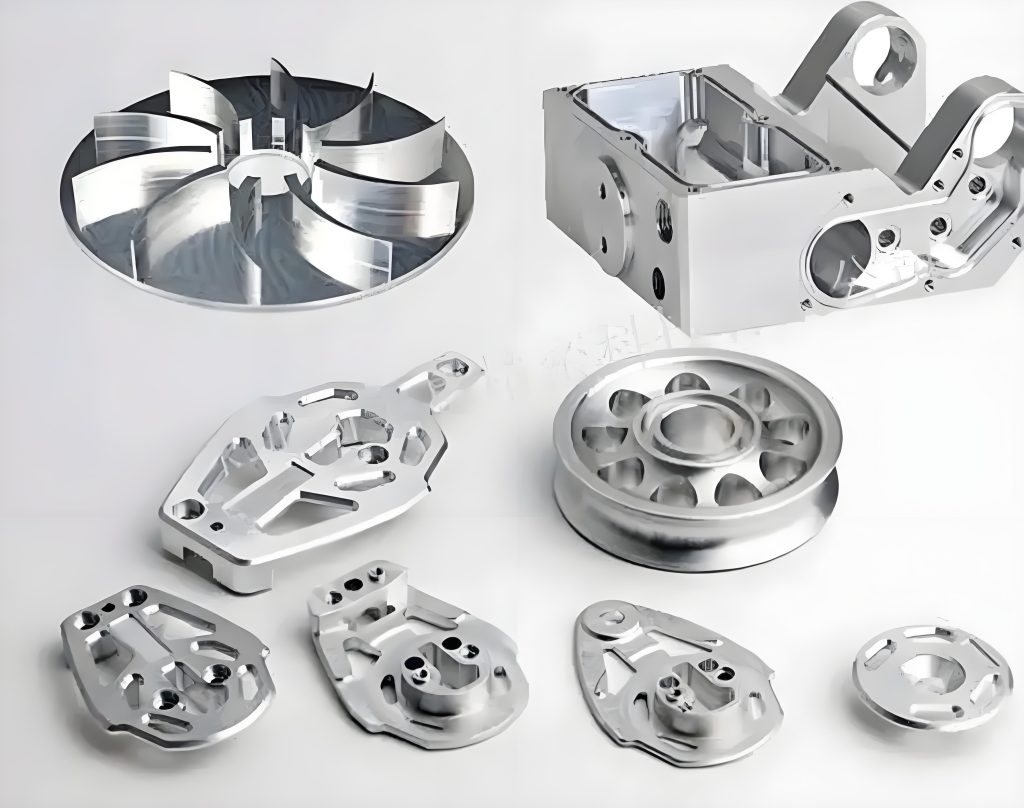

1. Advanced Precision with State-of-the-Art CNC Equipment

Rapidefficient leverages top-tier CNC equipment to produce components that require tight tolerances. Their cutting-edge technology is designed to handle the demands of medical machining, creating parts that are consistent and accurate, ensuring that every device functions as intended.

2. Streamlined Production Process for Faster Turnaround

With rapid prototyping and production capabilities, Rapidefficient can reduce lead times, enabling medical manufacturers to bring products to market faster. This quick turnaround is essential in an industry where time-sensitive projects are common, especially during new product launches.

3. Strict Quality Assurance Protocols

Each step in Rapidefficient’s production process undergoes rigorous quality checks, guaranteeing that components meet regulatory standards and customer specifications. This commitment to quality control ensures that every part performs reliably in critical medical applications.

4. Customization for Complex Designs

Many medical devices require custom designs or unique geometries to address specific patient needs or innovative device functionality. Rapidefficient’s CNC services allow for flexibility in design, making it possible to produce components tailored to each client’s exact specifications.

Applications of Mechanical Machining in Medical Devices

Mechanical machining serves as the foundation for manufacturing various essential medical components, such as:

- Surgical Instruments: CNC machining creates precise instruments like forceps, scalpels, and retractors, which are critical for successful surgeries.

- Implants and Prosthetics: CNC technology enables the production of custom implants with high accuracy, ensuring they fit perfectly and function reliably.

- Diagnostic Equipment Parts: Complex parts in diagnostic machines like MRI and CT scanners require precise manufacturing to maintain accurate readings and safe operation.

- Orthopedic and Spinal Devices: From screws to specialized plates, CNC machining ensures orthopedic devices are crafted to withstand high-stress environments in the human body.

Rapidefficient: A Reliable Partner in CNC Mechanical Machining for Medical Devices

Experience and Expertise in Medical Manufacturing

With years of experience in the CNC machining field, Rapidefficient understands the unique needs of the medical device industry. Their team is skilled in producing high-quality components that are consistent with regulatory requirements, providing clients with peace of mind and a trusted manufacturing partner.

Cost-Effective Solutions for High-Quality Production

Rapidefficient prioritizes efficiency in every aspect of its operations. By reducing material waste and maximizing production efficiency, they offer medical manufacturers cost-effective solutions that still meet the highest standards of quality.

Focus on Innovation and Reliability

In an industry that is always evolving, Rapidefficient continuously adopts new technologies and best practices. This focus on innovation means they stay current with industry standards, offering reliable, cutting-edge solutions for their clients.

Conclusion: Choose Rapidefficient for Trusted CNC Machining in Medical Manufacturing

When it comes to mechanical machining for medical devices, Rapidefficient is a trusted partner that offers precision, quality, and reliability. Their expertise in CNC machining enables them to produce complex, high-tolerance parts that meet the stringent requirements of the medical field. For a dependable manufacturing partner dedicated to excellence, choose Rapidefficient to bring your medical device designs to life.