有许多方法来加工CNC车床零件的内孔和表面, 包括 钻孔, 旋转, 无聊的, 转动, 磨削, broaching, lapping, honing, and rolling.

Applicable Methods for Machining Internal Holes of CNC Lathe Parts

Enlarging (Semi-finishing)

Enlarging is the process of further processing an already drilled hole using an enlarging drill to increase the diameter, improve accuracy, and reduce surface roughness.

- 厚度: IT11 to IT10

- 表面粗糙度: Ra12.5 to 6.3μm

It is considered a semi-finishing method for holes and is often used as a pre-processing step before reaming. It can also be used as a final finish for holes with low precision.

1. 钻孔

Drilling a hole in a solid part of a workpiece with a drill is called roughing.

- 厚度: IT13 to IT11

- 表面粗糙度: Ra50 to 12.5μm

This is because twist drills are long, have small core diameters, and lack rigidity, and are also affected by the chisel edge.

2. 铰孔

Reaming is a finishing method for holes following semi-finishing (enlarging or semi-finishing boring).

- 厚度: IT9 to IT6

- 表面粗糙度: Ra3.2 to 0.8μm (special cases up to Ra0.4–0.2μm)

There are two methods for reaming:

- Machine reaming: performed on a machine tool

- Manual reaming: performed manually

3. Hole Turning

Hole turning on a lathe involves rotating the workpiece while the tool moves.

- The hole size can be controlled by the tool’s depth of cut and number of passes.

- Mainly used for producing holes in components such as discs and small brackets.

4. 无聊的

Boring involves further processing a drilled, cast, or forged hole using a boring tool. This can be performed on a lathe, boring machine, or milling machine.

Types of boring:

- Rough boring: Tolerance IT13–IT12, Ra12.5–6.3μm

- Semi-finishing boring: Tolerance IT10–IT9, Ra6.3–3.2μm

- Finishing boring: Tolerance IT8–IT7, Ra1.6–0.8μm

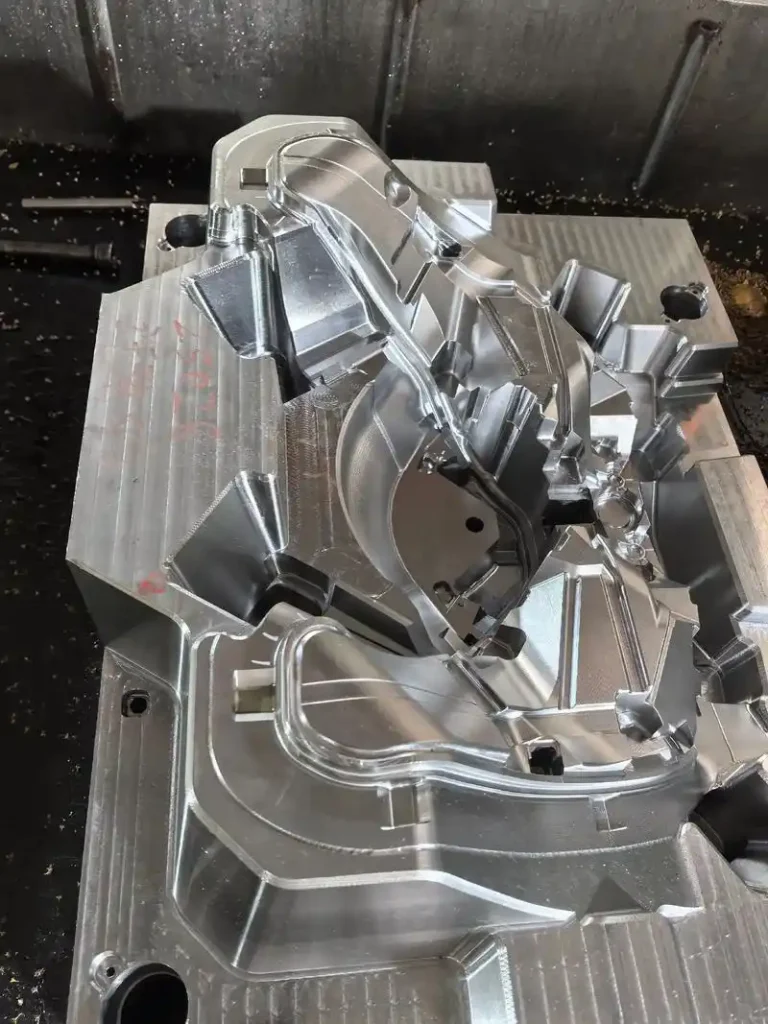

快速效果

迅速的 specializes in high-precision CNC machining with 18 多年的经验.

Its products cover:

- 医疗

- Communications

- Optics

- Drones

- Intelligent robots

- 汽车

- Office automation parts

The company’s CNC machining centers include 四轴, five-axis and linkage machine tools, and are equipped with precision projectors, 三坐标测量机, spectrometers and other precision testing equipment.

- 加工精度: 0.01毫米

- 测试准确性: 0.001毫米