Types of CNC Machining Datums

To study the relative relationship of part surfaces, a datum must be determined. A datum is a point, line, or...

Choosing Methods for Machining Internal Holes and Surfaces of CNC Lathe Parts

There are numerous methods for machining the internal holes and surfaces of CNC lathe parts, including drilling, reaming, boring, turning,...

Six Processes That Can Easily Influence Machining Errors

The slightest carelessness during machine tool processing can lead to errors. Below are six processes that can easily cause machining...

CNC Precision Parts Machining: Precise Control in the Micron World

In the precision arena of modern manufacturing, CNC (Computer Numerical Control) precision parts machining plays an irreplaceable central role. It...

Precision Parts Manufacturing: The Art of Micron and the Industrial Cornerstone

In the grand narrative of industrial civilization, those parts that are small, complex in structure, and require high precision often...

What are the technical difficulties and precautions for CNC 4-axis machining?

CNC 4-axis machining adds a rotary axis (usually the A-axis, rotating about the X-axis, or the B-axis, rotating about the...

Which industries require high precision in precision CNC machining?

Industries such as aerospace, medical devices, and automotive manufacturing place high demands on precision CNC machining. Products in these industries...

Analysis of the Characteristics and Advantages of Horizontal CNC Machining Centers

In the field of precision parts machining, the status of CNC machining centers is undeniable. CNC machining centers are divided...

Causes and Solutions for Lackluster Surface Finishes on Aluminum Alloy Housing Parts

CNC machining centers are capable of precision machining components for a wide range of applications, including copper alloys, stainless steel,...

CNC precision machining: the “core engine” of auto parts manufacturing upgrades

In today’s automotive industry’s pursuit of higher performance, stronger safety, and stricter environmental protection, the precision of each component is...

Precision Metal Processing: A thousandth of a millimeter contest for intelligent manufacturing in the future

Imagine a coin-sized piece of metal covered with a complex maze of microfluids, each channel with a width error of...

What factors affect the surface roughness of CNC-machined parts, and how can we reduce it?

In CNC machining, surface roughness is one of the key indicators of product quality. It not only affects the appearance...

New Development of Cutting Technology for Difficult-to-Machine Materials

Introduction: The Significance of Advanced Cutting Technology In modern Machining material cutting technology, difficult-to-machine materials have found extensive applications across...

Advantages of hardware CNC lathe processing

I. Introduction In the modern manufacturing landscape, hardware CNC lathe processing stands as a cornerstone technology. It plays a pivotal...

How to improve the finish of cnc four-axis machining?

I. Introduction In the realm of modern manufacturing, CNC four-axis machining stands as a cornerstone technology, enabling the production of...

The main characteristics of precision machining and ultra-precision machining

I. Introduction In the modern manufacturing landscape, precision machining and ultra-precision machining have emerged as the cornerstones of innovation and...

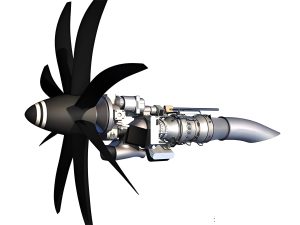

Aerospace Parts Processing: Unveiling Advanced Technologies and the Value of Rapidefficient

I. Introduction In the realm of modern manufacturing, aerospace parts processing stands as a pinnacle of precision, complexity, and technological...

The processing process of automobile parts processing method

1. Introduction Automobile parts processing is the backbone of the automotive industry. Each vehicle on the road today is the...

CNC machining center program code (Collection)

1. Introduction to CNC Machining Centers In modern manufacturing, CNC (Computer Numerical Control) machining centers play a pivotal role. They...

Aluminum alloy parts processing technology

What Are Aluminum Alloy Parts? Aluminum alloy parts are components made from alloys in which aluminum is the primary metal,...

How to reduce the deformation during CNC machining?

1. Introduction In the realm of CNC machining, achieving precision and accuracy is of paramount importance. However, one of the...

Common Problems in Aluminum Alloy Processing

I. Introduction Aluminum alloy processing plays a crucial role in various industries, from aerospace and automotive to construction and electronics....

How to avoid bumping accidents in CNC machining

1. Introduction In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone technology. It empowers...

Analysis of numerical control machining of base shaft hole system parts in agricultural machinery

I. Introduction In the realm of agricultural machinery manufacturing, the base shaft hole system plays a pivotal role. It is...

Precision Manufacturing, Protecting Lives: CNC Machining is the core solution in the field of medical devices

Under the shadowless light, the titanium alloy orthopedic implant in the surgeon’s hand is accurately fitting the patient’s bone; In...

Rapidefficient: Your expert in CNC machining service solutions

In the modern manufacturing battlefield that pursues efficiency and precision, the precision parts behind every product are the silent declaration...

The Duo of Speed and Precision: The Winning Way to Choose a CNC Machining Service Provider

In today’s rapid-paced manufacturing arena, “time is money” is no empty phrase. Production line shutdown due to delays in critical...

How Rapid Efficient Pushes CNC Machining Services to New Heights of Efficiency

In today’s competitive manufacturing landscape, precision and efficiency are the lifeblood of survival. Enterprises are not only looking for qualified...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. However, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

Affordable Mechanical Machining Services Without Compromising Quality

Introduction In today’s manufacturing world, finding affordable mechanical machining services that also deliver quality and reliability is crucial. Businesses across...