Aluminum alloy CNC machining parts: advantages and disadvantages of different models

Aluminum alloys are widely used in CNC machining due to their light weight, high strength, good thermal conductivity and corrosion...

Stainless steel CNC machining parts: advantages and disadvantages of different models

Stainless steel is widely used in CNC machining due to its excellent corrosion resistance, high strength and temperature resistance. Different...

Brass CNC machining parts: advantages and disadvantages of different models

Brass, as an alloy of copper and zinc, is highly favored in the field of CNC machining due to its...

Plastic CNC machining parts: pros and cons of different models

Plastic CNC machining parts: advantages and disadvantages of different models In modern manufacturing, plastic materials occupy an important position in...

How to improve the yield and output of precision parts?

In CNC processing manufacturers, the problems of low parts yield and insufficient production often lead to delayed delivery to customers,...

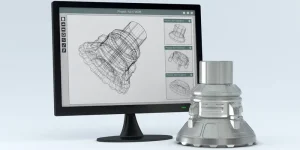

What does CNC machining DFM feasibility mean?

In the manufacturing industry, DFM (Design for Manufacturability) is a crucial concept. The purpose of DFM is to consider the...

How to evaluate the capabilities and experience of a parts CNC machining plant?

Choosing a suitable CNC processing manufacturer is very important to the success of your project. If you are looking for...

How to improve the precision of aluminum alloy CNC machining

In the process of aluminum alloy CNC machining, many manufacturers will face a common problem: how to improve machining accuracy?...

CNC machining production cycle: How long does it take from design to finished product?

When talking about CNC machining, many people think of the production and processing of precision parts. However, in the actual...

430 stainless steel and 321 stainless steel, which CNC processing is more resistant to high temperatures?

As a manufacturer specializing in CNC machining of precision parts, I often encounter customers who are confused when choosing materials,...

Medical precision parts CNC machining importance application

Medical components are essential for countries with aging populations. In addition, the growth of this industry is affected by rising...

Standard process steps for CNC machining

The standard process of CNC machining is generally 7 steps, and each process is required to be carried out in...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introduction In recent years, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

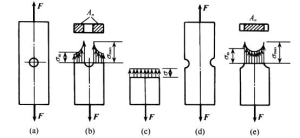

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

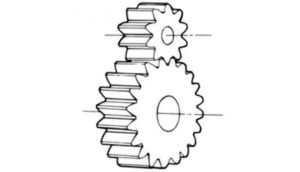

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

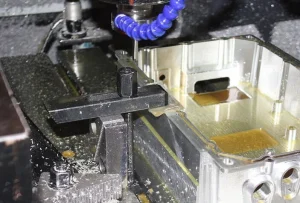

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

Cleaning methods and precautions for metal parts processing

1、Introduction to metal parts processing Metal parts processing is a crucial aspect of various industries, playing a significant role in...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...