The “Invisible Champion” of Precision Instrument Manufacturing: How Rapidefficient Empowers Cutting-Edge Technology with CNC Machining Services

In the world of precision instruments, even the slightest difference can be a thousand miles. From scalpels that manipulate cells...

CNC Machining Services: The “Life Guardians” of Medical Device Precision Manufacturing

Surgical robots that move precisely under shadowless lights, microscopic catheters that travel through blood vessels, orthopedic implants that silently support...

Key Advantages of CNC Swiss-type Machining

CNC Swiss-type machining centers, a sliding headstock automatic lathe that has become increasingly popular in recent years, offer versatile capabilities,...

What are the precision machining processes for different types of copper materials?

Common copper materials include: brass (an alloy composed of copper and zinc), cupronickel (an alloy composed of copper and nickel),...

Aluminum CNC Lathe Processing Process

Aluminum CNC lathe processing is a highly precise and widely used manufacturing method in modern industry. It combines advanced machining...

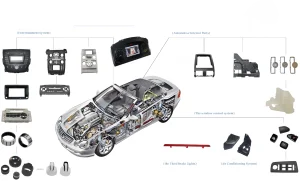

An Inventory of Precision Automotive Parts Processing

Every car is made up of thousands of precision parts, each serving a unique function. With over a century of...

Solutions for the Difficulty of Machining Stainless Steel Parts

Machining, as we commonly refer to it, involves using a cutting tool to remove excess material from a blank or...

Is CNC machining precision stainless steel parts really that difficult?

Common stainless steel precision parts are typically manufactured using standard grades such as 303, 304, 316, and 420. Stainless steel...

When Precision Meets the Sky: The Rigorous Art of CNC Machining in Aerospace

A modern airliner has millions of parts, and many of its key components, from engine turbine blades to landing gear...

CNC Machining Services: Precision Manufacturing Codes Beyond “OEM”

When you hand over a precision part drawing to a CNC machining service provider, do you expect them to just...

Materials and Main Accessories Used in Valve Precision Parts Processing

1. Main Accessories of Valves 2. Valve Body Materials Valve body materials should be selected according to pressure, temperature, corrosion...

What is boring on a CNC machining center? What are its benefits and challenges?

Boring refers to the process of enlarging or refining an existing hole in a workpiece. CNC boring is characterized by...

Post-processing of SLS Printed Parts

I. Introduction In recent years, the advent of 3D printing technology has revolutionized manufacturing, and Selective Laser Sintering (SLS) has...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introduction In recent years, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

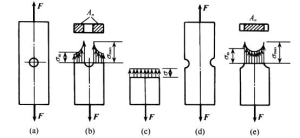

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

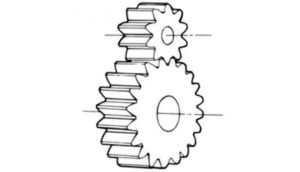

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. However, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

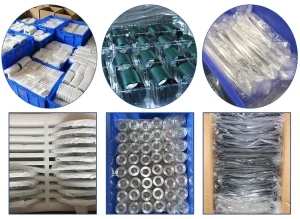

Packaging and Shipping Strategies for Safe Transportation of CNC Machined Parts

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

CNC Processing Plant for Collaborative Robot Parts

Collaborative robot parts are revolutionizing the manufacturing industry. These robots work alongside humans to enhance productivity and efficiency. At the...

Intelligent equipment parts CNC machining fast solution

1. Introduction In today’s highly developed manufacturing industry, intelligent equipment plays a crucial role in various fields. From industrial automation...

Marine equipment parts CNC machining fast solution

I. Introduction In recent years, the marine engineering industry has been booming, with the global demand for marine resources exploration,...