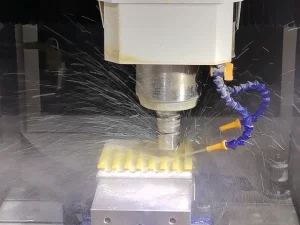

What factors should be considered when selecting cutting tools?

When selecting cutting tools, appropriate cutting tools and tool holders should be selected based on the function of the machining...

How can CNC 4-axis machining improve efficiency and quality?

In CNC 4-axis machining, improving efficiency and ensuring quality require a coordinated effort across multiple aspects, including process planning, programming...

What are the requirements of the CNC 4-Axis Machining Technical Standard?

CNC 4-axis machining refers to the fourth-axis rotary milling process on CNC machine tools. It adds a rotary axis (A-axis)...

Chatter Marks in CNC Machining and Solutions

Chatter marks in CNC machining are often caused by a variety of factors. Here are some possible solutions: CNC Machining...

Common Troubleshooting Methods for Stainless Steel Part Processing

Stainless steel part processing involves the fabrication of functional parts from stainless steel sheet metal using a variety of cold...

How to control costs and production management in non-standard hardware parts processing?

Non-standard hardware parts processing refers to hardware custom-made to specific customer requirements (such as non-standard size, shape, or function) that...

Let’s Learn About the Advantages of CNC Milling and Turning

CNC milling and turning is an advanced CNC machining technology that integrates multiple machining functions, including turning, milling, drilling, and...

What are the key points for quality control in stainless steel part processing?

Stainless steel part processing refers to the process of transforming raw materials (such as stainless steel plates, bars, pipes, and...

How to reduce part breakage during machining while maintaining dimensional accuracy?

In component manufacturing, dimensional accuracy and breakage risk are often intertwined. The higher the dimensional accuracy requirements, the more complex...

What are the typical applications of CNC 4-axis machining?

CNC 4-axis machining is a CNC machining method that adds a rotary axis (usually the A or B axis) to...

How to remove knife marks produced during stainless steel machining?

Knife marks (cutting marks) produced during stainless steel machining are surface defects caused by friction between the tool and the...

How can we ensure quality when processing non-standard hardware parts?

The processing quality of non-standard hardware parts (metal parts with non-standard specifications and customized to specific needs) directly impacts equipment...

Post-processing of SLS Printed Parts

I. Introduction In recent years, the advent of 3D printing technology has revolutionized manufacturing, and Selective Laser Sintering (SLS) has...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introduction In recent years, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

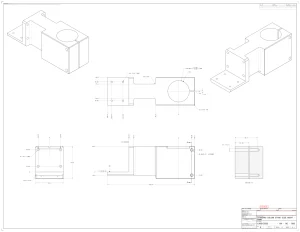

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

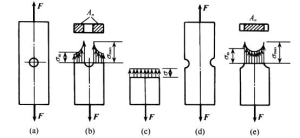

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

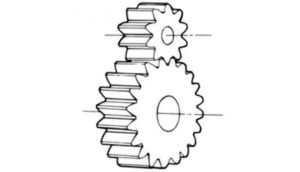

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

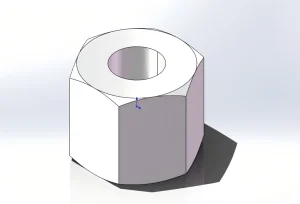

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

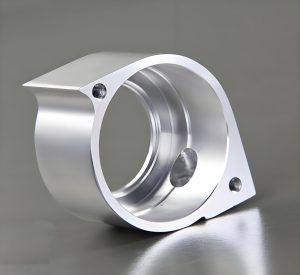

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

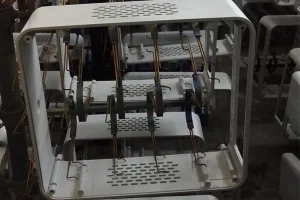

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...

Affordable Mechanical Machining Services Without Compromising Quality

Introduction In today’s manufacturing world, finding affordable mechanical machining services that also deliver quality and reliability is crucial. Businesses across...