What are the requirements of CNC 4-axis machining technical standards?

CNC 4-axis machining refers to the fourth-axis rotary milling of CNC machine tools. It is a machining method that adds...

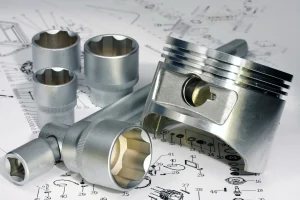

What are the factors that affect the quality of non-standard hardware parts processing?

The factors that have a greater impact on the processing of non-standard hardware parts are the material of the processing...

Understand how to solve the problems encountered during precision parts processing?

Precision parts processing is a demanding manufacturing process that requires the use of advanced processing technology and equipment to ensure...

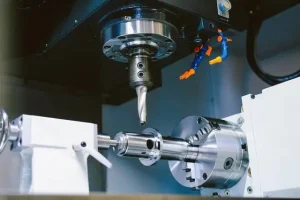

What is the main working principle of CNC turning and milling?

CNC turning and milling composite machining refers to the use of CNC systems to control the movement of workpieces between...

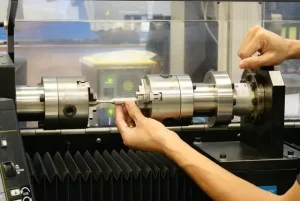

How to check abnormal problems during CNC turning and milling?

Checking abnormal problems that occur during CNC turning and milling can be done from the following aspects: 1. Equipment inspection:...

What are the forms of precision CNC machining?

There are various forms of precision CNC machining to meet the processing needs of different workpieces and materials. The following...

What are the requirements for the specifications and dimensions of stainless steel parts processing?

The specifications and size requirements of stainless steel parts processing are mainly affected by multiple factors, including the material properties...

Analysis of the reasons affecting the poor quality of precision CNC machining materials?

Operator quality and skills 1. Insufficient skill level: Precision CNC processing technology requires operators to have high professional skills and...

Do you want to know the development trend of precision parts processing?

1. Intelligence With the rapid development of technologies such as artificial intelligence and the Internet of Things, the precision parts...

What should be paid attention to in the polishing operation of precision parts?

1. Preliminary preparation Tool and material selection: Precision parts processing selects appropriate polishing tools according to the material, shape and...

How to control deformation during the processing of stainless steel parts?

In the process of stainless steel parts processing, controlling deformation is an important link, which directly affects the quality and...

How to solve the surface wear of precision CNC machined parts?

In precision CNC machining, wear on the surface of parts is a common problem, which may be caused by a...

High-Precision CNC Machining: Setting New Standards in Part Manufacturing

In the ever-evolving world of manufacturing, precision and efficiency are paramount. High-Precision CNC Machining has emerged as a game-changer, revolutionizing...

Customized processing of composite robot components based on drags

Introduction The Rise of Composite Robot Components In modern industry, the role of composite robot components has become increasingly prominent....

Machining of Small Components for Robots

Introduction The Significance of Small Components in Robotics In the realm of robotics, Small Components for Robots play a role...

Precision micro-component processing

1. Introduction 1.1 The Significance of Precision Micro-components In modern manufacturing, precision micro-components play a pivotal role. These tiny yet...

2024 China CNC High-Speed Machining Center Machine Industry Research Report

In the rapidly evolving world of manufacturing, China has emerged as a global leader in the CNC high-speed machining center...

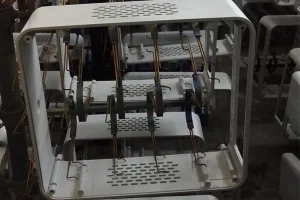

Electronic assembly mechanical parts Processing

Electronic assembly machinery forms the backbone of modern manufacturing, enabling the production of intricate electronic devices. Behind this efficiency lies...

All Kinds of Testing Machinery and Equipment Parts Processing

Introduction Testing machinery plays a critical role in various industries, ensuring the quality, durability, and functionality of products. As industries...

Why will the precision of precision hardware parts become worse?

Introduction In the world of manufacturing, precision hardware parts processing is of utmost importance. Precision hardware parts are the building...

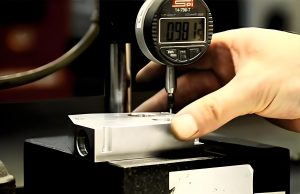

What are the measurement methods for precision parts processing accuracy?

Introduction In the field of precision parts machining measurement, ensuring high – level processing accuracy is of utmost importance. The...

Non-standard titanium alloy parts customized

Introduction In contemporary manufacturing, the demand for non – standard titanium alloy parts customized is on the rise. Titanium alloy,...

Titanium processing process

Introduction Titanium, a remarkable metal, has been captivating the attention of various industries due to its unique set of...

Importance of tungsten steel for precision parts processing

Introduction In the world of precision parts processing, tungsten steel has emerged as a material of utmost importance. Its unique...

Aluminum CNC Prototyping: Revolutionizing Product Development with Rapidefficient

1. Introduction In the highly competitive landscape of modern manufacturing, Aluminum CNC prototyping has emerged as a cornerstone for innovation...

Unleashing the Power of CNC Aluminum Parts Manufacturing with Rapidefficient

1、Introduction In today’s rapidly evolving industrial landscape, CNC aluminum parts manufacturing plays a crucial role. This article aims to provide...

CNC Aluminum Machining Services: Unleashing Precision and Efficiency

Introduction Overview of CNC Aluminum Machining CNC aluminum machining is a highly sophisticated and essential process in various industries. This...

High-Precision Aluminum CNC Machining: A Comprehensive Overview

1、Introduction to High-Precision Aluminum CNC Machining High-precision aluminum CNC machining is a crucial process in modern manufacturing. It involves the...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

High-Precision Multi-Hole Flange Connection Plate

I. Choosing the Right Material Eliminates the Risk of Later Defects For this component, we initially had two material options...

Aluminum alloy precision valve body

1、 Choosing the right materials saves 80% of the trouble in the later stage We use 6061-T6 aluminum alloy (compliant...

Stainless steel porous precision mechanical sleeve:the “sturdy protective umbrella” of equipment.

Introduction In industrial equipment, if there is a component that can be like a “sturdy steel armor”, tightly protecting the...

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

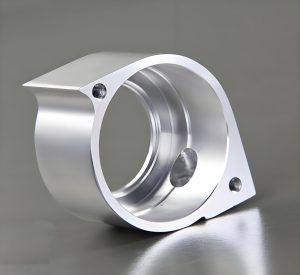

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

High – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, and...

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...