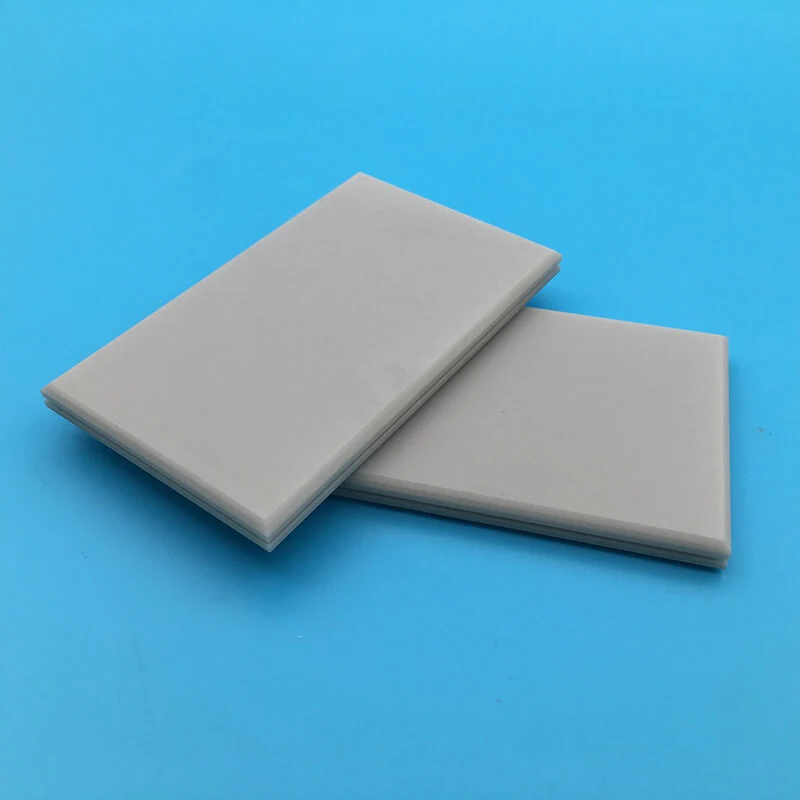

Aluminiumnitridkeramik sind ein Material mit ausgezeichneter thermischer Leitfähigkeit, und ihr Anwendungsbereich nimmt allmählich zu. Although aluminum nitride ceramics are excellent, their precision machining is a challenge. Can conventional CNC machining centers process aluminum nitride ceramics? Many people may have this question. While it is theoretically possible to machine aluminum nitride with a standard CNC machine, it is generally not recommended. Instead, specialized ceramic machining equipment such as ultrasonic machining centers or laser machines is preferred.

Aluminum nitride ceramics are inherently hard and brittle, making them very prone to edge chipping. Heute, join RapidEfficient to learn about aluminum nitride ceramic machining methods. CNC-assisted machining is a particularly challenging step, particularly during the drilling process, where edge chipping is most likely to occur. To address this issue, consider the following methods:

Method 1: Leave Stock and Use CNC Finishing

Während der Bearbeitung, leave sufficient stock on the part and then proceed with precision CNC finishing. Nach der Bearbeitung, edge chipping will inevitably occur on the back of the part. Using a grinder to remove the excess material can eliminate this edge chipping.

Jedoch, this method also has drawbacks, primarily material loss. Ceramics are generally expensive, which increases processing costs. Während der Bearbeitung, a smaller diameter tool is used, and spiral cutting is employed, grinding the holes layer by layer. This method requires a slower tool speed, which means it’s less efficient. Jedoch, it does have its advantages: the inner hole wall is relatively smooth compared to direct drilling.

Method 2: Pilot Hole and Expansion

Another approach is to use a smaller diameter tool to create a pilot hole, then gradually expand it to the desired size. This may cause machining marks to appear on the inner hole wall. Start drilling on the smaller side, drill about halfway through, remove the part, flip it over, and drill again, aligning the two holes.

After machining is complete, this method has the disadvantage of not guaranteeing perfect alignment of the two holes. Jedoch, this misalignment is often minimal and acceptable for many applications.

Abschluss

Abschließend, aluminum nitride ceramics have excellent thermal, electrical, and mechanical properties, but because they are both hard and brittle, machining them is far more challenging than metals. Specialized methods such as ultrasonic machining, laser machining, or grinding are usually combined with CNC finishing to achieve the best results.

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive and office automation parts. The company’s CNC machining centers include four-axis, five-axis and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers and other precision testing equipment. The machining accuracy can achieve 0.01mm and the testing accuracy can achieve 0.001mm.