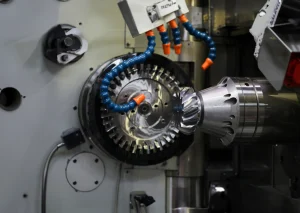

CNC machining centers are capable of precision machining components for a wide range of applications, including copper alloys, stainless steel, aluminum alloys, titanium alloys, and other materials. Jedoch, during the machining of aluminum alloy housing parts, sometimes unfinished work can lead to a less-than-smooth surface finish.

What causes this?

- The tool is damaged, causing it to be less sharp, or the coolant performance is substandard.

- The CNC machining equipment is not installed stably, causing vibration during machining of aluminum alloy housings.

- The lead screw on the equipment is crawling, or there is a problem with the CNC machining program, primarily related to feed rate, cutting amount, and spindle speed.

How to Solve It

- Whenever a tool is worn, it needs to be sharpened or replaced.

- If the CNC equipment is not installed stably, the level of the equipment needs to be recalibrated and secured.

- If the coolant performance is substandard, it needs to be replaced with a coolant suitable for aluminum alloy housing machining.

- Cracking usually indicates that the equipment guide rails or lead screws are worn or loose, requiring replacement of CNC machine parts and regular equipment maintenance.

- If there is a problem with the CNC programming, the CNC machining program needs to be adjusted, primarily adjusting the feed rate, cutting amount, and spindle speed.

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive, and office automation parts.

The company’s CNC machining centers include four-axis, five-axis, and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers, and other precision testing equipment.

- Machining accuracy: up to 0.01 mm

- Testing accuracy: up to 0.001 mm