Under the shadowless light, the titanium alloy orthopedic implant in the surgeon’s hand is accurately fitting the patient’s bone; In the ICU ward, delicate and complex ventilator components are silently maintaining the life channel. Behind these health-sustaining and life-saving medical devices, a key manufacturing technology is playing an irreplaceable role – CNC machining for medical devices. It is not only the molding process of metals or engineering plastics, but also the core solution for medical devices to achieve high precision, high reliability and strict compliance. The application of CNC machining for medical devices ensures that implants and instruments meet the strictest standards for human safety.

Tough Challenges in Medical Device Manufacturing

Unlike ordinary industrial products, medical devices are directly related to human life and health, and their manufacturing faces unique and stringent requirements:

Extreme Precision and Micron-Level Tolerances: From the slender tips of minimally invasive surgical instruments to the complex curved surfaces of artificial joints, dimensional accuracy often requires micron-level (μm) accuracy. Any minor deviation can lead to instrument failure, surgical failure, or patient discomfort.

Superior Biocompatibility and Material Requirements: Implants or components in long-term contact with the human body must use proven biocompatible materials (such as medical grade titanium alloy Ti6Al4V ELI, cobalt-chromium alloy, medical stainless steel 316LVM, PEEK, PEI, usw.). These materials are usually hard, tough, and significantly more difficult to process.

Impeccable Surface Finish and Cleanliness: The surface roughness must be minimal, preventing bacterial growth and reducing the risk of tissue friction or clotting. The processing process needs to strictly avoid contamination to ensure that the final product is sterile and residue-free.

Perfect Presentation of Complex Geometry: Modern medical device designs are becoming increasingly complex, such as personalized orthopedic implants, miniature complex structures of endoscopes, and fine occlusal surfaces of dental restorations, which require extremely high geometric freedom in processing technology.

Strict regulations and traceability: It must comply with strict global regulatory requirements (such as FDA, CE, GMP/ISO 13485 of China’s NMPA), and the production process must have complete traceability (material batch, processing parameters, inspection records, usw.).

CNC -Bearbeitung: Precision Solutions Tailored for the Medical Sector

In the face of these challenges, advanced CNC machining services have become an indispensable cornerstone of medical device manufacturing with their unique advantages:

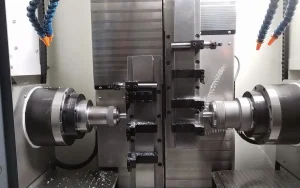

Unmatched Precision and Repeatability: Modern multi-axis CNC machines, such as 5-axis linkage, enable nanometer-level resolution motion control, effortlessly meeting the most demanding tolerances of medical devices (up to ±0.005mm or more). Procedural control ensures that every product in high-volume production is precise and consistent, which is critical for standardized instrumentation and large-scale production.

Navigating “Difficult-to-Gnaw” Medical Materials: CNC machining centers are equipped with high-performance spindles, rigid structures, and advanced tools (such as diamond-coated and ceramic tools) to efficiently and stably process difficult-to-machine materials such as titanium alloys, cobalt-chromium alloys, and PEEK, ensuring dimensional accuracy and surface quality.

Master of shaping complex three-dimensional geometry: Whether it is the complex curved surface of a skeletal bionic structure or the precision groove on a micro sensor, 5-axis CNC technology can complete multi-angle and multi-faceted machining through a single clamping, perfectly presenting the designer’s intention and achieving complex parts that cannot be reached by traditional machining methods.

Superior Surface Finish and Cleanliness: CNC machining itself can achieve excellent surface roughness (Ra < 0.4μm is common). Combined with subsequent specialized finishing for medical applications (e.g., electropolishing EP, passivation, micro-arc oxidation MAO), ultra-smooth, corrosion-resistant, and biocompatible surfaces can be obtained. Strict cleaning procedures (e.g. ultrasonic cleaning, cleanroom environment) are carried out throughout the process.

Built for Compliance: Professional CNC service providers in the medical field, their core value extends far beyond machining capabilities. They are well versed in the medical device regulatory system:

ISO 13485 Zertifizierung: This is the cornerstone of the quality management system in medical manufacturing, ensuring controlled, traceable, and risk-controlled throughout the entire process, from design, procurement, production, to service.

Complete Verification and Confirmation: Strict equipment verification (IQ/OQ/PQ) and process verification (PPQ) ensure that the machining process is stable and reliable, and the output meets expectations.

Complete traceability system: Realize the whole process of data recording and tracking from raw material warehousing to finished product shipment, meeting regulatory audit requirements.

Cleanroom Environment: Critical processes are conducted in a controlled clean environment to prevent particulate contamination.

Key Elements of Choosing a Medical-Grade CNC Partner

When selecting a CNC machining service provider, medical device manufacturers should look beyond basic machining capabilities and focus on the maturity of their “medical-grade” solutions:

Deep industry experience and success stories: Do you have long-term experience in serving well-known medical device customers? Have you successfully delivered products of similar complexity (e.g., orthopedic implants, surgical robotic components, core parts for high-end diagnostic equipment)?

Comprehensive Accreditation: ISO 13485 certification is a mandatory threshold to check its certification status and scope. Others such as ISO 9001, ISO 14001, usw. are also the embodiment of management level.

Material expertise and supply chain management: Are you familiar with the characteristics and processing difficulties of various medical materials? Do you work with reliable, medically qualified raw material suppliers? Can you provide complete proof of materials (CoC, MTRs)?

Advanced equipment and process capabilities: Do you have high-precision multi-axis CNC machine tools, turning/milling composite centers? Do you have special processes for the medical industry (e.g. precision micromachining, medical grade polishing, special coatings)?

Rigorous quality control system: Is the laboratory equipped with high-precision testing equipment (such as CMM, profiler, roughness meter, spectrum analyzer)? Are the inspectors professional? Is Process Control (SPC) Effectively Enforced?

Design & Manufacturing Integration Services: Can you provide design for manufacturability (DFM) optimization recommendations? This is critical to reducing costs, improving yields, and accelerating time-to-market.

Project Management and Communication Skills: Under strict regulations and tight timelines, clear and efficient communication and project management are key guarantees for project success.

Abschluss: Präzision, More than Technology

In the field of medical devices, CNC machining has leapt from a mere “Herstellung” link to a “core solution” to ensure product performance, safety, and compliance. It represents a commitment to the unremitting pursuit of ultimate precision, the supreme reverence for life and health, and a deep understanding and strict enforcement of stringent global regulations. When a doctor holds a precision instrument and implants an artificial joint in the patient’s body, behind it is CNC technology that silently guards the dignity and hope of life with micron-level “ingenuity”. Choosing a CNC partner like Schnell with deep medical expertise and comprehensive solution capabilities is the cornerstone of medical device companies’ strategies for successfully developing innovative products, winning market trust, and ultimately benefiting patients worldwide. Precision manufacturing, at this moment, is truly synonymous with protecting life.