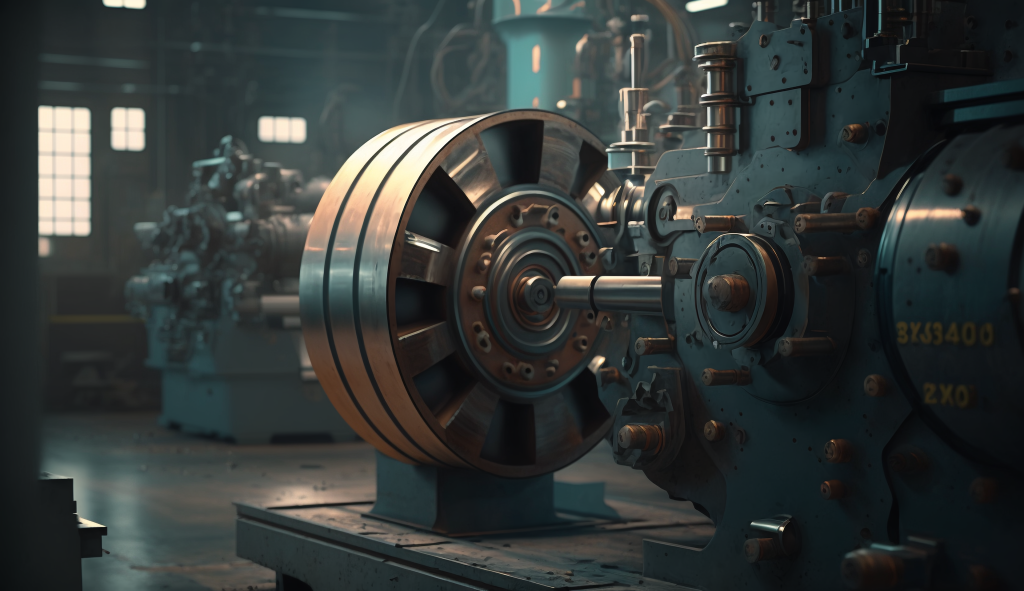

In der modernen Fertigung, CNC -Drehungen sind mit ihrer hohen Präzision unverzichtbare Verarbeitungsgeräte geworden, hohe Effizienz, und hohe Automatisierung. For companies and individuals engaged in mechanical processing, it is very important to understand the key components of CNC lathes. So, what are the key components of CNC lathes? There are mainly three, let us unveil their mystery together.

one、Spindle system

The spindle system is one of the core components of CNC lathes,Its performance directly determines the processing accuracy and efficiency of the machine tool。Based on the latest technological perspectives,Spindle systems are moving towards high speed、High precision、Highly rigid directional development。

- Spindle motor

Spindle motors power the lathe’s spindle,Its power and speed determine the size and material of the workpiece that the machine tool can process。now,The high-performance spindle motor adopts advanced permanent magnet synchronous technology,Has fast response speed、Large torque、High efficiency and other advantages。at the same time,In order to meet different processing needs,Some CNC lathes are also equipped with variable speed spindle motors,Able to adjust the speed according to actual conditions during processing。

- Spindle bearings

Spindle bearings support the rotation of the spindle,Its accuracy and rigidity have an important impact on processing accuracy。at present,Commonly used spindle bearings include rolling bearings and sliding bearings.。Rolling bearings have a small friction coefficient、High speed、Good accuracy retention and other advantages,Suitable for high-speed processing;Sliding bearings have large load-bearing capacity、Good vibration resistance and other characteristics,Suitable for heavy-duty processing。When choosing spindle bearings,It needs to be comprehensively considered based on the processing requirements and the performance characteristics of the machine tool.。

- Spindle box

The spindle box is the shell of the spindle system,It not only protects the spindle and bearings,It is also responsible for transmitting power and adjusting speed.。When designing the spindle box,The rationality of its structure needs to be considered、Sealing and heat dissipation。Some advanced CNC lathe spindle boxes adopt a modular design,Easy to repair and replace parts,It is also equipped with automatic lubrication system and cooling system,To ensure the normal operation of the spindle。

two、Fütterungssystem

The feed system is a key component of CNC lathes for precise machining,It is responsible for controlling the tool at X、Y、Z movement in three directions。

- ball screw

The ball screw is the core component of the feed system,It converts the rotational motion of the motor into linear motion of the tool。Compared with traditional lead screw,Ball screws have high precision、Small friction coefficient、High transmission efficiency and other advantages。When choosing a ball screw,Need to consider its accuracy level、lead、Diameter and other parameters,To meet different processing requirements。at the same time,In order to improve the accuracy and stability of the feeding system,Some CNC lathes also use a combination of double-nut preloaded ball screws and linear guides。

- Servo motor

Servo motors power the feed system,Its performance directly affects the processing accuracy and speed of the machine tool。Modern servo motors use digital control technology and AC permanent magnet synchronous technology,Has fast response speed、High precision、Advantages such as large torque。in the course of work,The servo motor cooperates with the CNC system,Able to achieve precise position control and speed control,This ensures that the tool is processed according to the predetermined trajectory.。

- guide

The guide rail is the supporting component of the feeding system,It ensures the straightness and stability of the tool during movement。at present,Commonly used guide rails include sliding guide rails and linear guide rails.。The sliding guide rail has a simple structure、Low cost and other advantages,But the friction coefficient is large、Low accuracy;Linear guides have high precision、Small friction coefficient、Long life and other advantages,Suitable for high speed、High precision machining。When choosing rails,It needs to be comprehensively considered based on the processing requirements and the performance characteristics of the machine tool.。

three、CNC system

The CNC system is the “brain” of the CNC lathe,It is responsible for controlling the various components of the machine tool to work together,Enable precise machining。

- Hardware part

The hardware part of the CNC system mainly includes the central processing unit、memory、Input and output interfaces, etc.。The central processing unit is the core of the CNC system,It is responsible for executing CNC programs,Control the movement of various parts of the machine tool。Memory is used to store CNC programs and machining data,Input and output interfaces are used to communicate with external devices。When choosing a CNC system,Need to consider the performance and reliability of its hardware,To ensure the stable operation of machine tools。

- Software part

The software part of the CNC system mainly includes the operating system、Programming software and control software, etc.。The operating system is the basis of the CNC system,It is responsible for managing hardware resources,Provide a running environment for other software。Programming software for writing and editing CNC programs,The control software is responsible for controlling the movement of each component of the machine tool.。When choosing a CNC system,Need to consider the functionality and ease of use of their software,To improve the efficiency of programming and operation。

- Human-computer interface

The human-machine interface is the window for interaction between the CNC system and the operator.,Its design directly affects the operator’s experience。The modern CNC system human-machine interface adopts touch screen technology and graphical interface design,Easy to operate、Intuitive。at the same time,Some CNC systems are also equipped with remote monitoring and diagnostic functions,Convenient for operators to maintain and manage machine tools。

The continuous development of CNC machining technology,It has brought many positive impacts to scientific and technological progress.。it improves production efficiency,Reduced production costs,Makes processing of complex parts easier。at the same time,CNC machining technology also promotes the intelligence of manufacturing industry、Automation development,To realize industrial 4.0 laid the foundation。

Now that we know what the key components of CNC lathes are, if you are looking for a reliable CNC -Bearbeitung supplier, Rapid Efficient CNC machining supplier is definitely a good choice. They have advanced CNC lathe equipment and a professional technical team, and can provide customers with high-quality and efficient CNC machining services. Whether it is precision parts processing or mass production, Rapid Efficient can meet your needs. Choosing Rapid Efficient means choosing quality and trust.