Rapidefficient views every project as a new challenge, and this one was no exception.

Background

In early 2023, we partnered with NordicSafe Solutions, a forward-thinking smart home security company based in Stockholm, Sweden. NordicSafe Solutions holds a significant market share in the Nordic region, generating approximately €35 million in annual revenue. They provide technology products that embrace minimalist lifestyles, serving residents from frozen Oslo to rainy Helsinki. Demand for new electronic door locks surged, with users seeking stylish and durable designs that could withstand harsh winters while maintaining aesthetic appeal. We stepped in at the right time, leveraging our CNC expertise to precisely realize their vision.

Challenges and Requirements

NordicSafe is launching a line of electronic door locks inspired by fashionable prototypes. These unusual locks, featuring touchscreens, keypads, and wireless connectivity, can be integrated with systems like Philips Hue and Samsung SmartThings, making them ideal for tech-savvy Nordic users. However, the Nordic climate’s extremes demand top-tier durability.

The specific requirements are as follows:

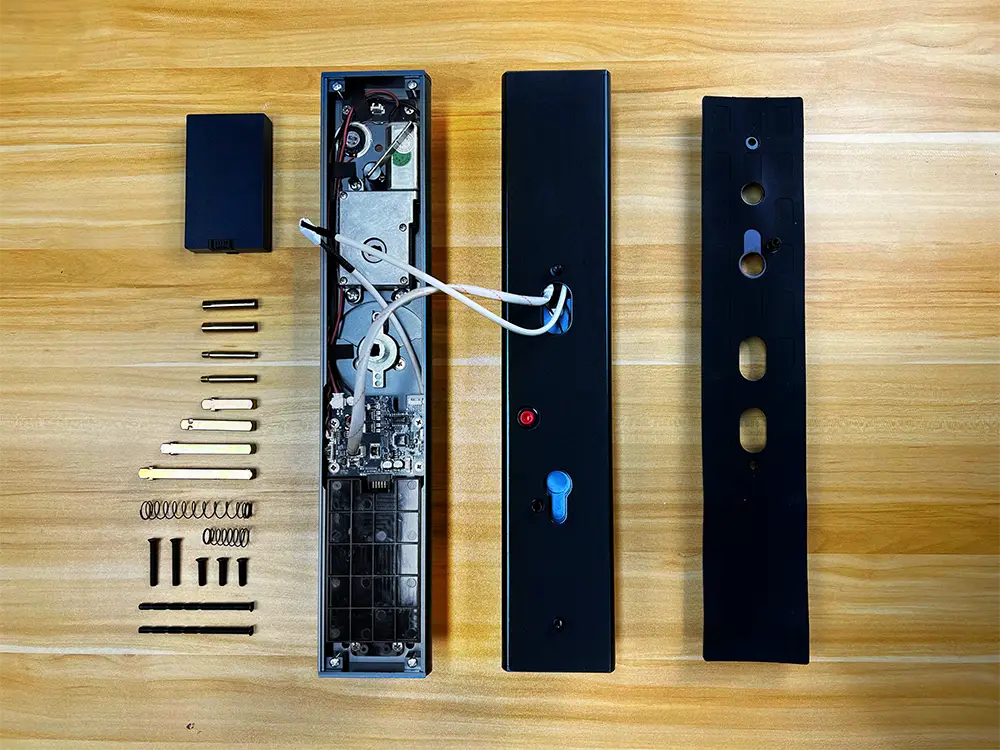

The main housing with the keypad required a slim chassis approximately 280 mm long, with a keypad slot tolerance of ±0.01 mm—the buttons and sensors had to be perfectly synchronized to prevent malfunction. Made of 6061-T6 aluminum alloy, it weighed less than 350 grams to fit within lightweight Nordic doors and achieved an IP66 rating for snow and rain resistance. The sealing groove was machined to a depth of 1.5 mm, with no rough spots on the surface.

The handle and locking mechanism feature a smooth, curved lever design (with a fluid arc and ergonomic grip). These require a tight 3mm radius for smooth operation, and the pins are drilled to an accuracy of ±0.006mm. Imagined for constant use in a busy household, they must withstand 150,000 cycles and require a surface roughness of Ra 0.3μm to prevent frost accumulation. The new design required precision milling of the 10mm-thick lever, with a polished transition to the base for a premium feel.

Internal components and assembly involve multi-layer milling of gears, rings, and circuit brackets. Battery slots and wiring channels are precision-engineered to ±0.005mm to avoid short circuits in sub-zero temperatures, crucial in regions like Lapland.

These specifications were extremely demanding—micron-level precision was uncompromising; any deviation could cause the lock to jam or pose a security risk. The order was for 1,500 units, with a delivery time of just seven weeks. They had to meet CE safety standards and emphasize sustainability: 92% recyclable materials and near-zero waste. The budget was tight, in line with Nordic environmental principles.

Our Approach

We emphasize customized solutions. Leveraging AutoCAD software and optimized design, we reduced material usage by 12% through stress simulation while maintaining strength.

Specific implementations include:

CNC innovations—DMG Mori five-axis machines enable single-shot machining of complex shapes, such as handles. The keyboard housing is cut using a precision tool head at 14,000 RPM, ensuring tight tolerances and a smooth surface, reducing production time by 20%.

Intelligent technology—Laser deburring of gear edges ensures smooth operation in cold climates. A vacuum fixture securely holds parts during drilling to prevent shake. A 12μm hard anodized coating is applied for frost protection, and the serial number is laser-etched.

Strict inspections—A Mitutoyo coordinate measuring machine scans each part (over 60 points), and an AI vision system detects defects, resulting in a 99.6% yield rate. Freeze-thaw cycle testing at -30°C, simulating Swedish winter conditions, ensures reliability.

The entire process is completed in an automated factory in Shenzhen, providing real-time monitoring for NordicSafe. Initial tool wear issues were quickly addressed and resolved within 48 hours.

Significant Returns

1,500 locks were delivered ahead of schedule, without any defects, by the end of summer 2023. NordicSafe saw a 20% sales increase after its launch in the Nordic market, particularly in Norway, where its weatherproofing proved exceptional during blizzards. A manager at the Nordic company commented, “Rapidefficient has transformed locks into winter warriors—stylish and rugged!”

This successful collaboration has established our reputation in the Nordic region, and we are currently discussing upgrades with NordicSafe, including biometric authentication.

Rapidefficient specializes in the precision and speed of CNC machining. If you have any project requirements, please contact us. We are always here to help realize your vision.