Injection Molding Services: The precision manufacturing engine of modern manufacturing

Imagine the rugged case of your smartphone, the complex instrument cluster assembly inside a car, or the component in a...

The Art of Metal Bending: Efficient and Precise Solutions in Manufacturing Services

In the grand scheme of modern manufacturing, metal bending, a seemingly fundamental yet crucial process, acts like a low-key yet...

What factors influence CNC Swiss machining speed?

In modern manufacturing, CNC Swiss machining is an efficient, precise, and flexible process. It can be used to create products...

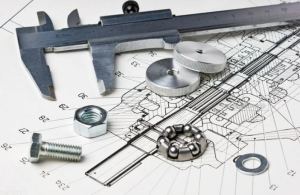

Essential Knowledge for CNC Machining of Precision Parts

We know that the emergence of CNC equipment is a significant milestone in technological advancement. It effectively addresses complex, precise,...

CNC Precision Parts Machining: Selection of Processing Methods and Division of Processes and Work Steps

In modern manufacturing, CNC precision parts machining requires not only high accuracy and excellent surface quality but also efficiency and...

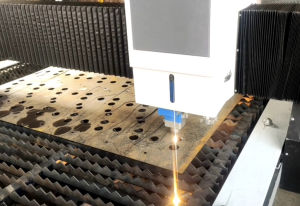

Laser Cutting: The Invisible Blade for Manufacturing Services Upgrades

In the early morning, when engineer Xiao Wang uploaded a complex stainless steel part design drawing to the cloud system...

A New Benchmark in Efficient Machining: CNC Turning and Rapidefficient’s Manufacturing Revolution

In the arena of manufacturing, time is cost, and precision is life. When traditional machining methods struggle to breathe in...

CNC Thread Machining Methods

Thread machining is one of the most commonly used operations in CNC machining. According to different machining methods, it can...

CNC Aluminum Machining: A Revolution in Efficiency and Precision in Precision Manufacturing

Aluminum, with its lightweight, high strength, corrosion resistance and excellent electrical and thermal conductivity, has become a core material in...

Types of CNC Machining Datums

To study the relative relationship of part surfaces, a datum must be determined. A datum is a point, line, or...

Choosing Methods for Machining Internal Holes and Surfaces of CNC Lathe Parts

There are numerous methods for machining the internal holes and surfaces of CNC lathe parts, including drilling, reaming, boring, turning,...

Six Processes That Can Easily Influence Machining Errors

The slightest carelessness during machine tool processing can lead to errors. Below are six processes that can easily cause machining...

New Development of Cutting Technology for Difficult-to-Machine Materials

Introduction: The Significance of Advanced Cutting Technology In modern Machining material cutting technology, difficult-to-machine materials have found extensive applications across...

Advantages of hardware CNC lathe processing

I. Introduction In the modern manufacturing landscape, hardware CNC lathe processing stands as a cornerstone technology. It plays a pivotal...

How to improve the finish of cnc four-axis machining?

I. Introduction In the realm of modern manufacturing, CNC four-axis machining stands as a cornerstone technology, enabling the production of...

The main characteristics of precision machining and ultra-precision machining

I. Introduction In the modern manufacturing landscape, precision machining and ultra-precision machining have emerged as the cornerstones of innovation and...

Aerospace Parts Processing: Unveiling Advanced Technologies and the Value of Rapidefficient

I. Introduction In the realm of modern manufacturing, aerospace parts processing stands as a pinnacle of precision, complexity, and technological...

The processing process of automobile parts processing method

1. Introduction Automobile parts processing is the backbone of the automotive industry. Each vehicle on the road today is the...

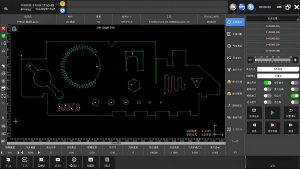

CNC machining center program code (Collection)

1. Introduction to CNC Machining Centers In modern manufacturing, CNC (Computer Numerical Control) machining centers play a pivotal role. They...

Aluminum alloy parts processing technology

What Are Aluminum Alloy Parts? Aluminum alloy parts are components made from alloys in which aluminum is the primary metal,...

How to reduce the deformation during CNC machining?

1. Introduction In the realm of CNC machining, achieving precision and accuracy is of paramount importance. However, one of the...

Common Problems in Aluminum Alloy Processing

I. Introduction Aluminum alloy processing plays a crucial role in various industries, from aerospace and automotive to construction and electronics....

How to avoid bumping accidents in CNC machining

1. Introduction In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone technology. It empowers...

Analysis of numerical control machining of base shaft hole system parts in agricultural machinery

I. Introduction In the realm of agricultural machinery manufacturing, the base shaft hole system plays a pivotal role. It is...

Parts processing technology and flow

The Core of Parts Processing Technology What is Parts Processing Technology Parts processing technology is the cornerstone of modern manufacturing,...

CNC Machining of Aluminum Alloy Material

The Basics of Aluminum Alloy in CNC Machining What is Aluminum Alloy? Aluminum alloy is a material composed mainly of...

Three Factors Affecting the Machining Accuracy of CNC Milling Machine and Four Solutions

1、Introduction to CNC Milling Machine Machining Accuracy 1. Briefly introduce what CNC milling machine machining accuracy means and its importance...

CNC solutions from Rapidefficient suppliers

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. This is where CNC (Computer Numerical Control) solutions come...

Explore Precision with Aerospace CNC Machining Solutions

Introduction Aerospace CNC machining is a critical aspect of the modern aerospace industry. This blog will explore the world of...

Rapid and Efficient Precision Machining and Manufacturing: A Comprehensive Review

ABSTRACT This paper explores the significance of rapid and efficient precision machining and manufacturing. It elaborates on the crucial role...

Precision CNC Machining Parts: Unraveling Excellence in Modern Manufacturing

ABSTRACT This paper thoroughly discusses various aspects of precision CNC machining parts. It clarifies that precision CNC machining parts are...

Unlock the Potential of Metal with Our Metal Precision Machining

ABSTRACT This paper thoroughly discusses metal precision machining, including its definition, importance, types of processing and characteristics. It elaborates on...

CNC Turning Service for Small Batch Production: Precision and Efficiency Unleashed

1、Introduction What is CNC Turning Service for Small Batch Production? CNC turning service for small batch production is a specialized...

CNC Turning Tools for Precision Machining: Unleashing Rapidefficient’s Excellence

1、Introduction In the realm of precision machining, CNC turning tools play an indispensable role. Precision machining is crucial for industries...

Unleashing the Cost Efficiency of CNC Machining Aluminum with Rapidefficient

一、Introduction In the realm of CNC machining aluminum, Rapidefficient emerges as a game-changer. Cost efficiency in CNC machining holds paramount...

CNC Machining for Aluminum Enclosures: Excellence in Precision Engineering

1. Introduction In the realm of modern manufacturing, CNC machining has revolutionized the production of aluminum enclosures. These enclosures serve...

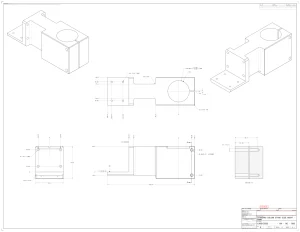

High-Precision Multi-Hole Flange Connection Plate

I. Choosing the Right Material Eliminates the Risk of Later Defects For this component, we initially had two material options...

Aluminum alloy precision valve body

1、 Choosing the right materials saves 80% of the trouble in the later stage We use 6061-T6 aluminum alloy (compliant...

Stainless steel porous precision mechanical sleeve:the “sturdy protective umbrella” of equipment.

Introduction In industrial equipment, if there is a component that can be like a “sturdy steel armor”, tightly protecting the...

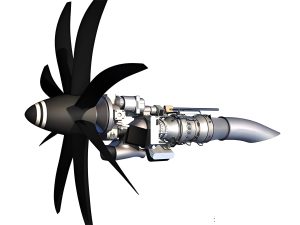

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

High – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, and...

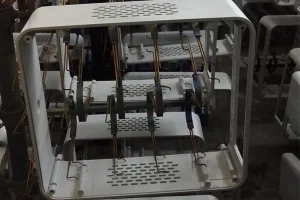

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...