Introduction

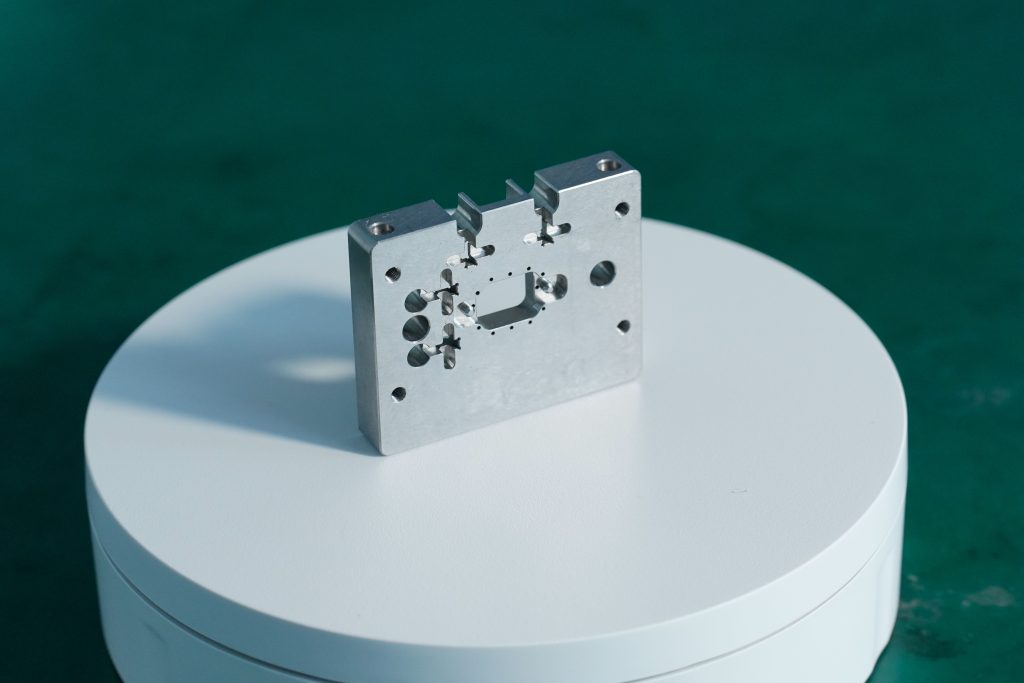

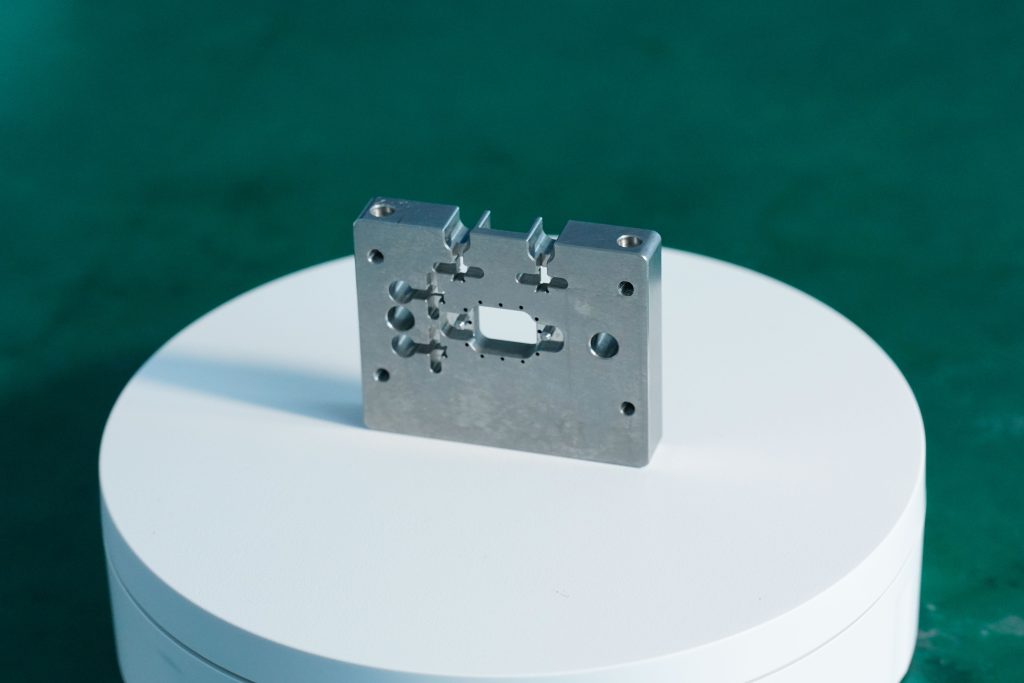

In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which can keep the various components in place and “make no mistakes” under high precision requirements, then the equipment will run much more smoothly. Our high-precision transmission gearbox housing can achieve such a function.

1. Material composition

This part is made of high-quality aluminum alloy (Aluminum Alloy 6061-T6), which has excellent mechanical properties and corrosion resistance and is suitable for various high-precision and high-strength industrial applications.

Aluminum alloy 6061-T6 composition characteristics: magnesium (1.0%), silicon (0.6%), iron (0.7%), copper (0.28%)

2. CNC processing process

This precision metal bracket is processed by CNC (computer numerical control) machine tools. The specific steps are as follows:

(1) Design and programming: First, engineers use CAD software to design the three-dimensional model of the part, and then use CAM software to convert it into G code that can be recognized by CNC machine tools.

(2) Material preparation: Select a suitable aluminum alloy block as the raw material and fix it on the CNC machine.

(3) Rough machining: Use a rough milling cutter to make a preliminary cut on the aluminum alloy block, remove excess material, and form a blank close to the final shape.

(4) Finishing: Replace the fine milling cutter and perform fine machining to ensure the dimensional accuracy and surface finish of the part.

(5) Drilling and tapping: According to the design requirements, use drill bits and tapping tools to drill and tap at the specified location.

(6) Deburring and polishing: After processing, remove the burrs on the edge of the part and polish it to improve the surface quality.

(7) Quality inspection: Finally, use a three-coordinate measuring machine (CMM) and other inspection tools to conduct a comprehensive inspection of the part to ensure that it meets the design requirements.

Of course,The precautions for processing are as follows:

Thin wall deformation prevention: The side wall of the shell is only 2mm thick, and layered cutting + low-temperature cooling technology is used.

Hole concentricity: The gear shaft hole must ensure a tolerance of ±0.02mm and use a reamer for fine finishing. lThread accuracy: All M3-M8 threaded holes use extrusion taps to avoid aluminum chips residue.

3. Structural features and functions

Multi-cavity design: Separates the gear groups to reduce vibration interference.

Heat dissipation fins: Naturally enhance air flow and extend gear life.

Waterproof groove structure: O-ring slot design, dust and splash proof (IP54 standard).

Function: Carrying the transmission system, accurately distribute power, suitable for robot joints and automation equipment transmission modules.

4. Practical application

Empowering the factory of the future: CNC gearbox housing, how to drive Germany’s top collaborative robots to dance accurately.

- Project background: A German innovative company specializing in high-precision collaborative robots. Their new generation of seven-axis collaborative robot “Aura-7” encountered a bottleneck in prototype testing. The gearbox housing provided by the original supplier will experience micron-level deformation after long-term high-speed operation, resulting in increased transmission backlash, which directly affects the repeatability of the robot arm (from ±0.05mm to more than ±0.1mm). This is fatal for the “Aura-7” robot, which performs precision assembly and inspection tasks. At the same time, they hope to further reduce weight to improve energy efficiency, but the weight reduction space of the original cast aluminum parts has reached its limit.

- Core needs: Find a CNC processing partner that can meet the requirements of “extreme precision and stability”, “lightweight” and “fast mass production”.

- Role positioning: This gearbox housing plays a comprehensive role of “joint bones” and “neurovascular channels” in the “Aura-7” robot. It is not only the housing that protects the precision harmonic reducer and motor, but also the precise installation benchmark for all transmission components.

- Why choose CNC processing instead of casting? Because “Aura-7” is in a rapid iteration stage, the mold opening cost is high and the cycle is long. Our CNC prototype service perfectly meets its “small batch, multiple batches, fast iteration” R&D and initial production needs.

- Project Achievements: l

Improved precision: After using our AL6061-T6 CNC to process the shell, the “Aura-7” robot maintained a repeatable positioning accuracy of ±0.03mm during a continuous 1,000-hour endurance test, far exceeding customer expectations. l

Weight optimization: Through topology optimization and thin-wall processing technology, the shell weight was reduced by 22% compared to the original design, helping to improve the robot’s energy efficiency. l

Delivery speed: From receiving the final 3D model to the delivery of the first 50 sets of qualified parts to the German customer, it took only 12 working days, helping the customer seize the market opportunity.

5. Conclusion

There are several reasons why customers choose us:

5-axis CNC + German process standards = one-step molding of complex structures

24-hour online engineering support, rapid response to design optimization

Exported to 40+ countries, anti-collision and moisture-proof packaging, delivered directly to the customer’s workshop

CNC prototypes not only perform well in the domestic market, but also have won wide recognition in the international market. Whether it’s material selection, processing technology, or quality control, we strive to be the best and provide our customers with the highest-quality products and services.

If you’re looking for a reliable CNC machining partner, please contact us. Let’s work together to create superior industrial parts!